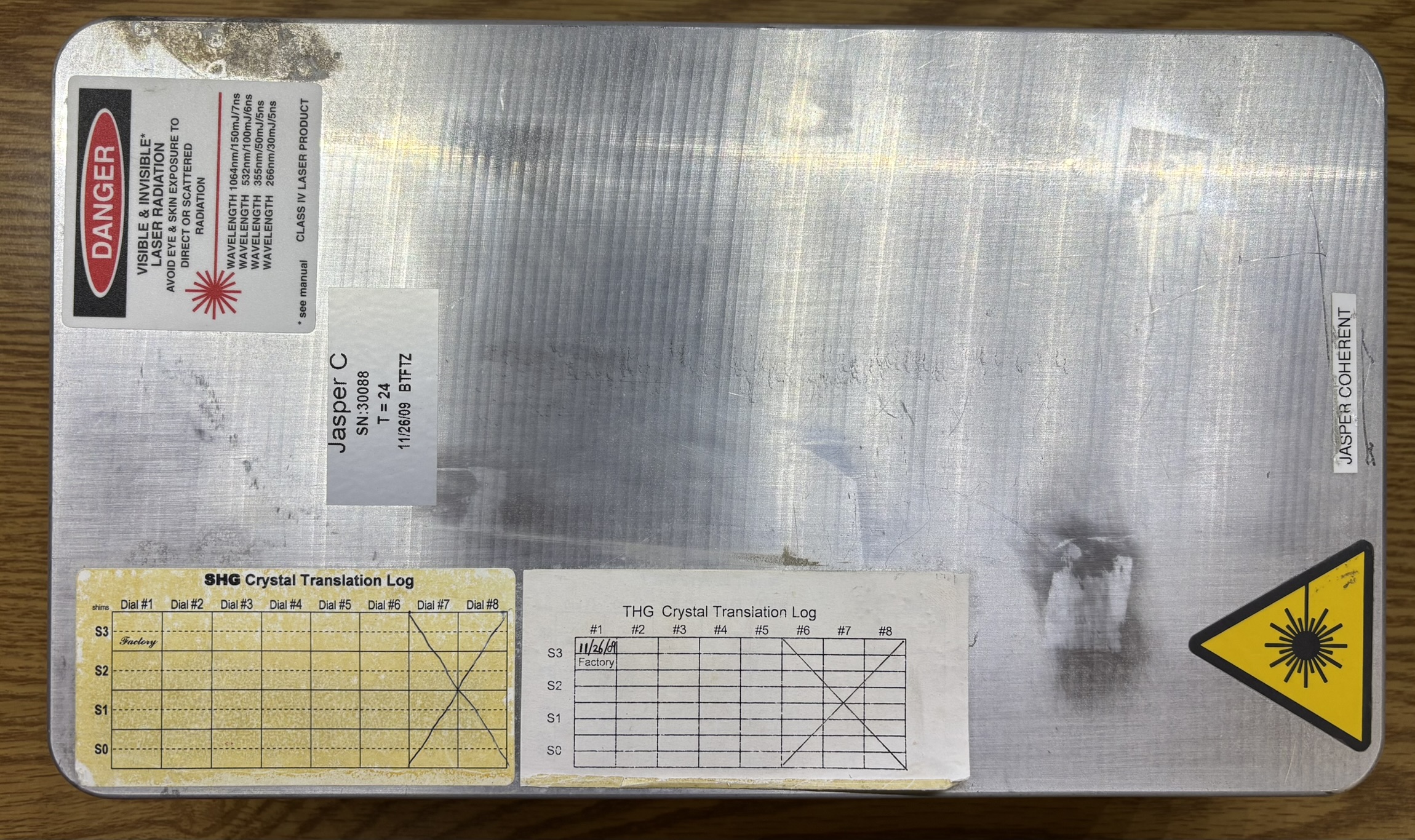

We obtained the Jasper HP from Starlight Photonics and are very grateful to work with them and examine this laser system. There is little documentation available online about the Jasper HP specifically. The enclosure is made of machined aluminum and the whole assembly weighs around 15 lbs. On the front, there is a mechanical beam shutter and an emission indicator. This laser uses an Nd:YAG crystal and both SHG and THG to convert between several wavelengths of laser light to achieve a final output of 355nm. There is also a built-in acoustic-optic modulator or q-switch that is used to increase the pulsed output power.

On the top, there are two labels that read "crystal translation log". Each crystal assembly is mounted to a platform that resembles a kinematic mount with a small rotating dial. The dial is an octagon with 8 numbered positions. This is used to move (or translate) the SHG and THG crystals very slightly without negatively affecting the system's alignment. The reason for this is to spread the wear evenly over the crystal surface during the laser's lifetime. Since the Jasper HP is a relatively powerful pulsed laser, the crystals could degrade if the beam was kept in the same spot indefinitely. The translation log allows the operator to keep track of the position as it is changed. We aren't sure how often a translation should take place but it likely corresponds to the amount of hours. On this particular laser, neither translation log has any entries aside from the factory one. Perhaps it was never done or just never added to the log.

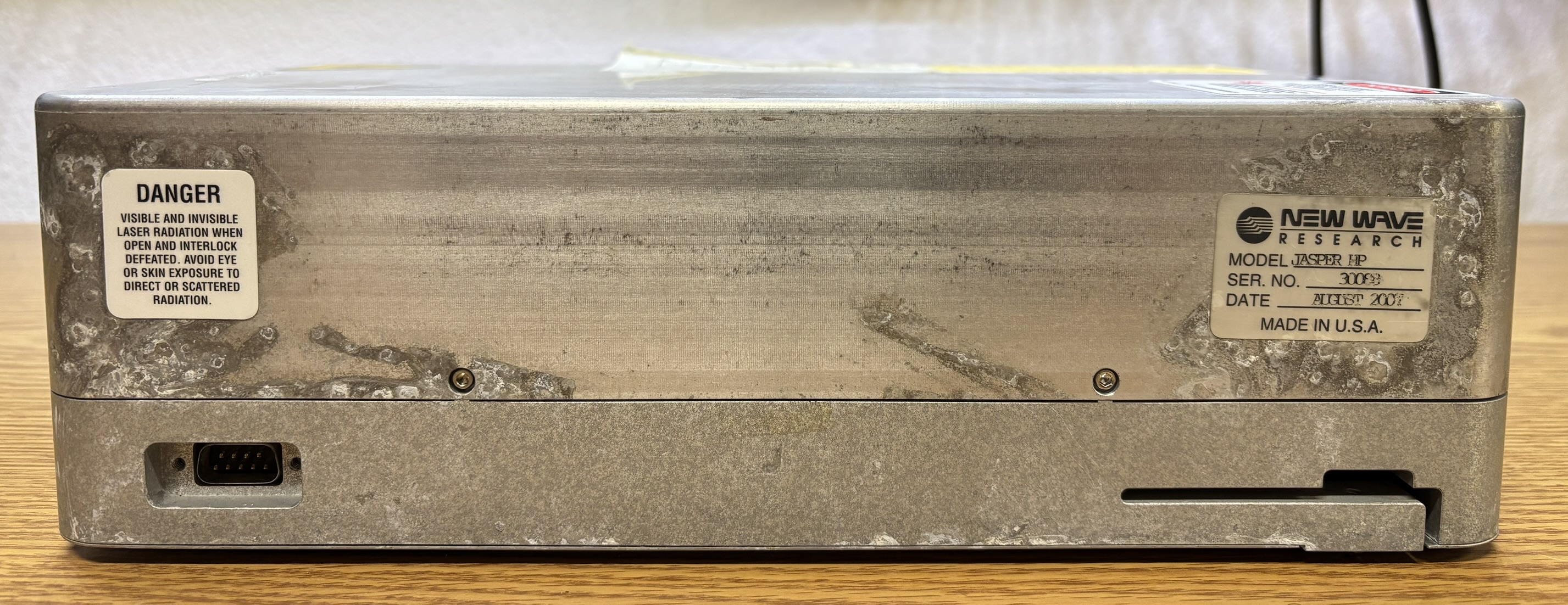

Since the Jasper HP is a water-cooled laser, there are two plastic quick-disconnects for the water inlet and outlet. The small brass hose barb may be used to flow dry nitrogen through the resonant cavity, especially since the casing is not well sealed. The SMA connector is for the internal q-switch. The q-switch driver is contained within the controller and not inside of the laser head. Lastly, is a high density D-SUB connector with a unique combination of traditional pins and high-current pins for the pump diode. The connector is manufactured by Positronic and has a part number of CBD46W4M2000Z.

On the side of the laser head is an information label that displays the model as JASPER HP and a manufacture date of AUGUST 2007. There is a male DB-9 connector recessed into the casing on the side. The internal connections from the DB-9 pass directly through to several pins of the large D-SUB connector on the back, it may be for a controller or other accessory.

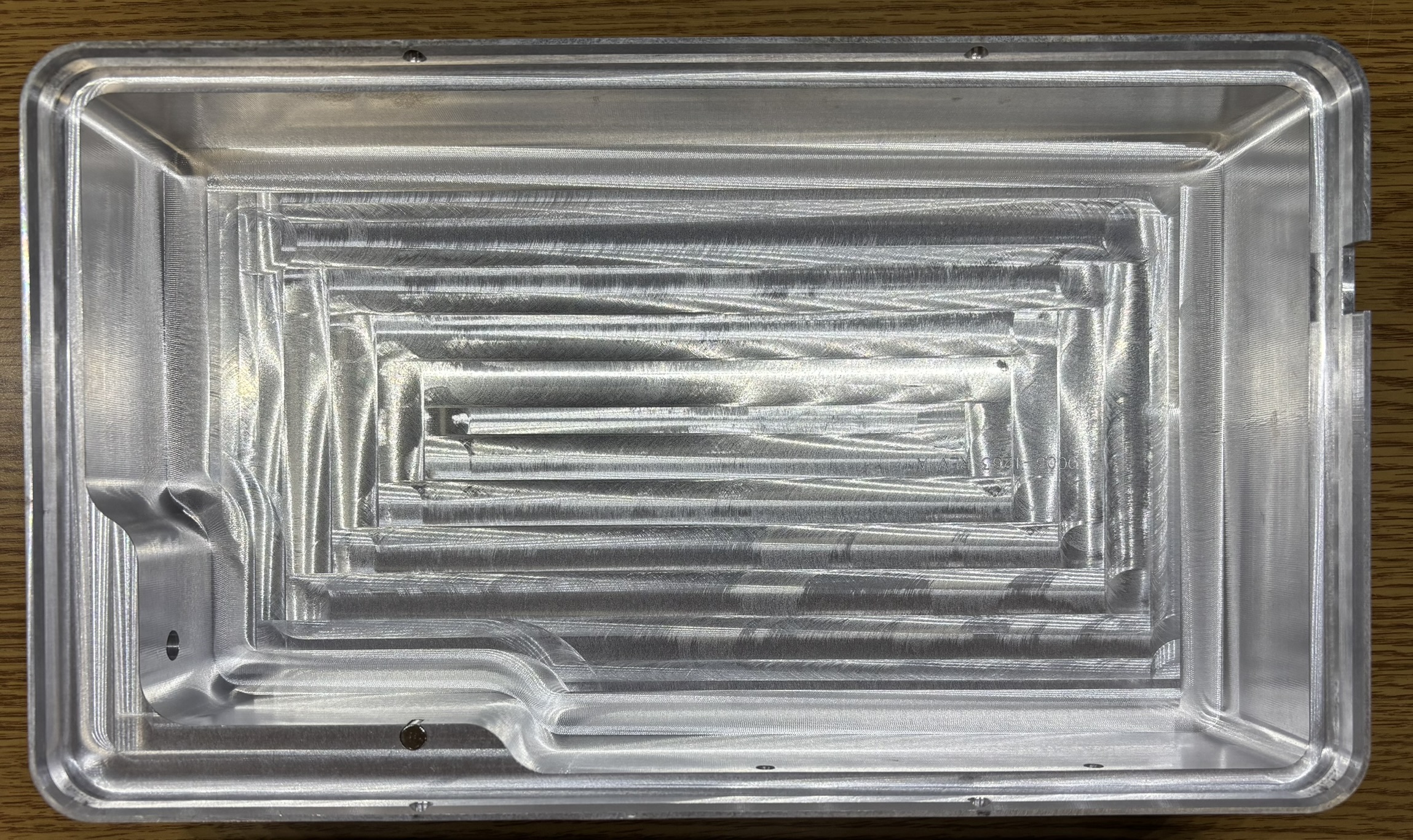

On the bottom of the laser head, there are three ball bearings pressed into the frame which act as feet for the laser. The bottom cover can be removed to access some connections and internal components.

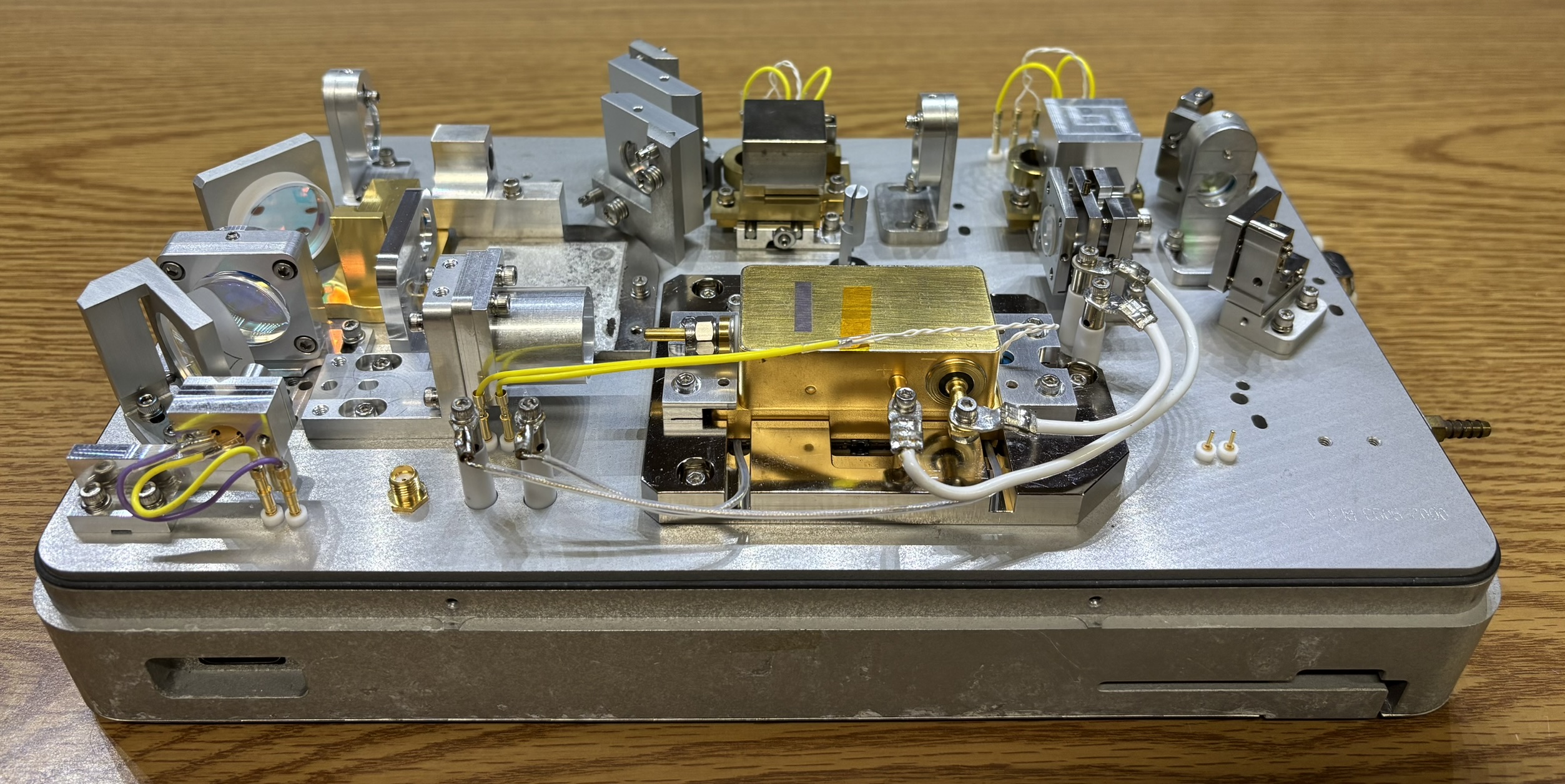

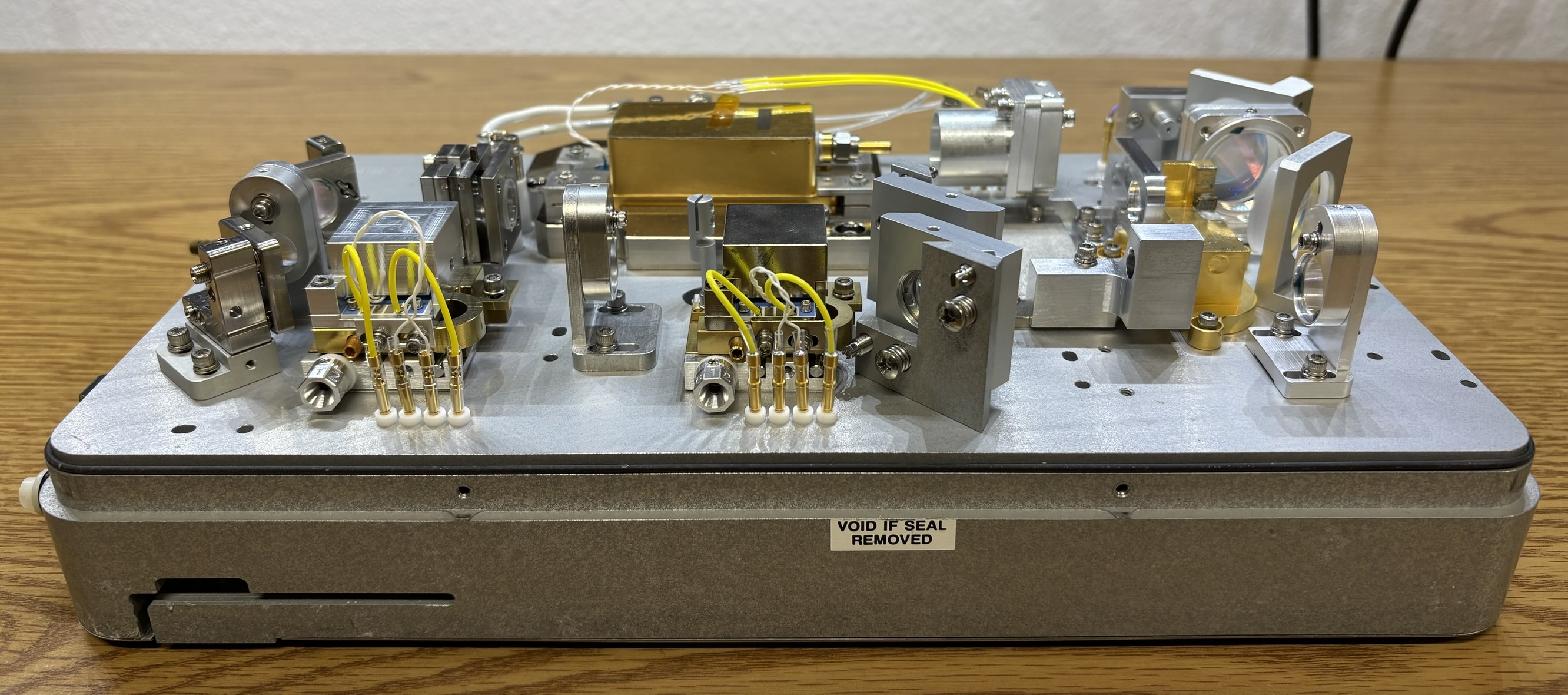

The top of the laser head comes off by removing four screws, two on each side. There is a sealing gasket around the entire cover mating surface to keep unwanted debris from making its way in and contaminating the optics. This laser system was likely used for material ablation, marking, or micro-machining, which would generate lots of dust and debris.

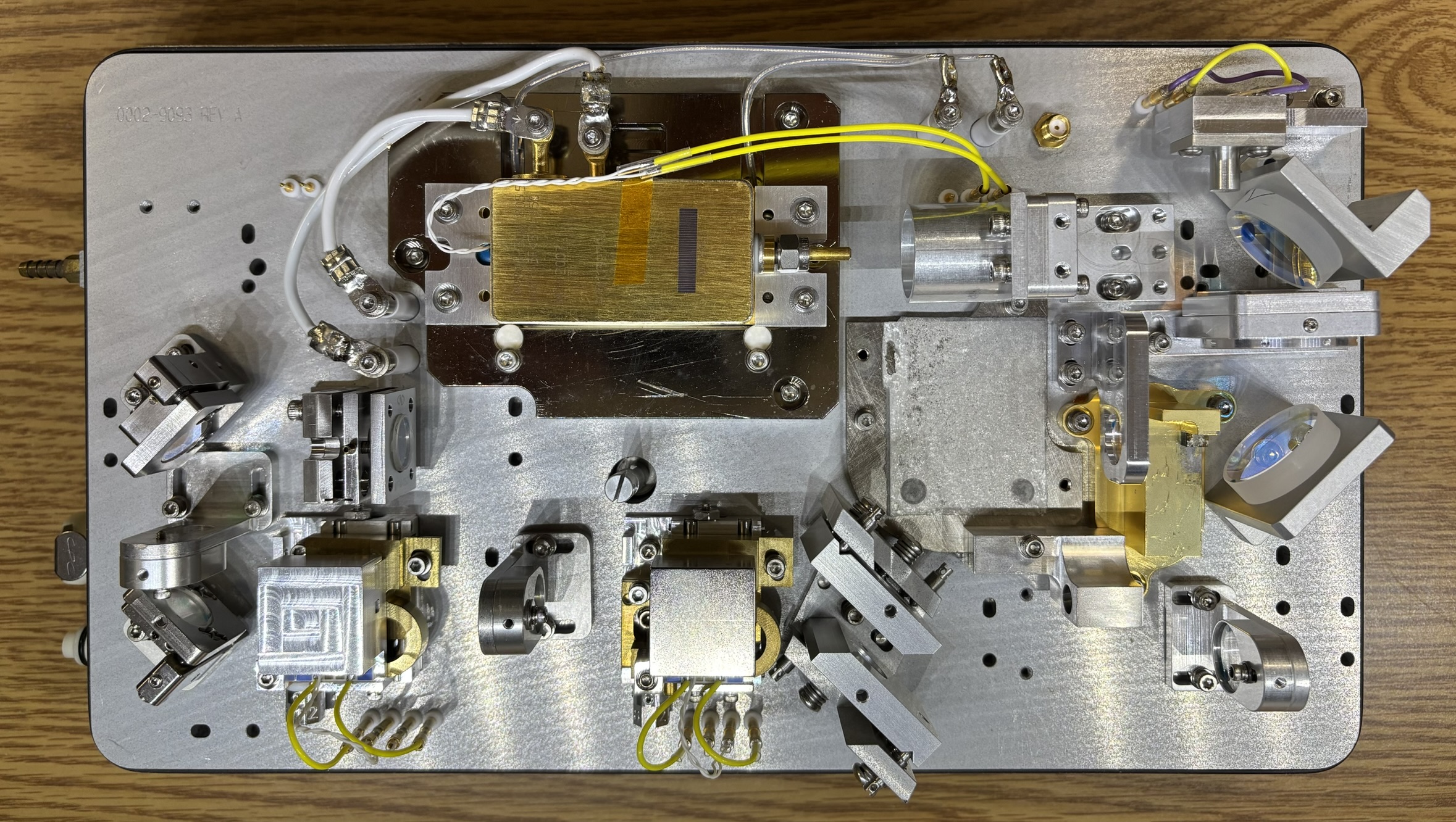

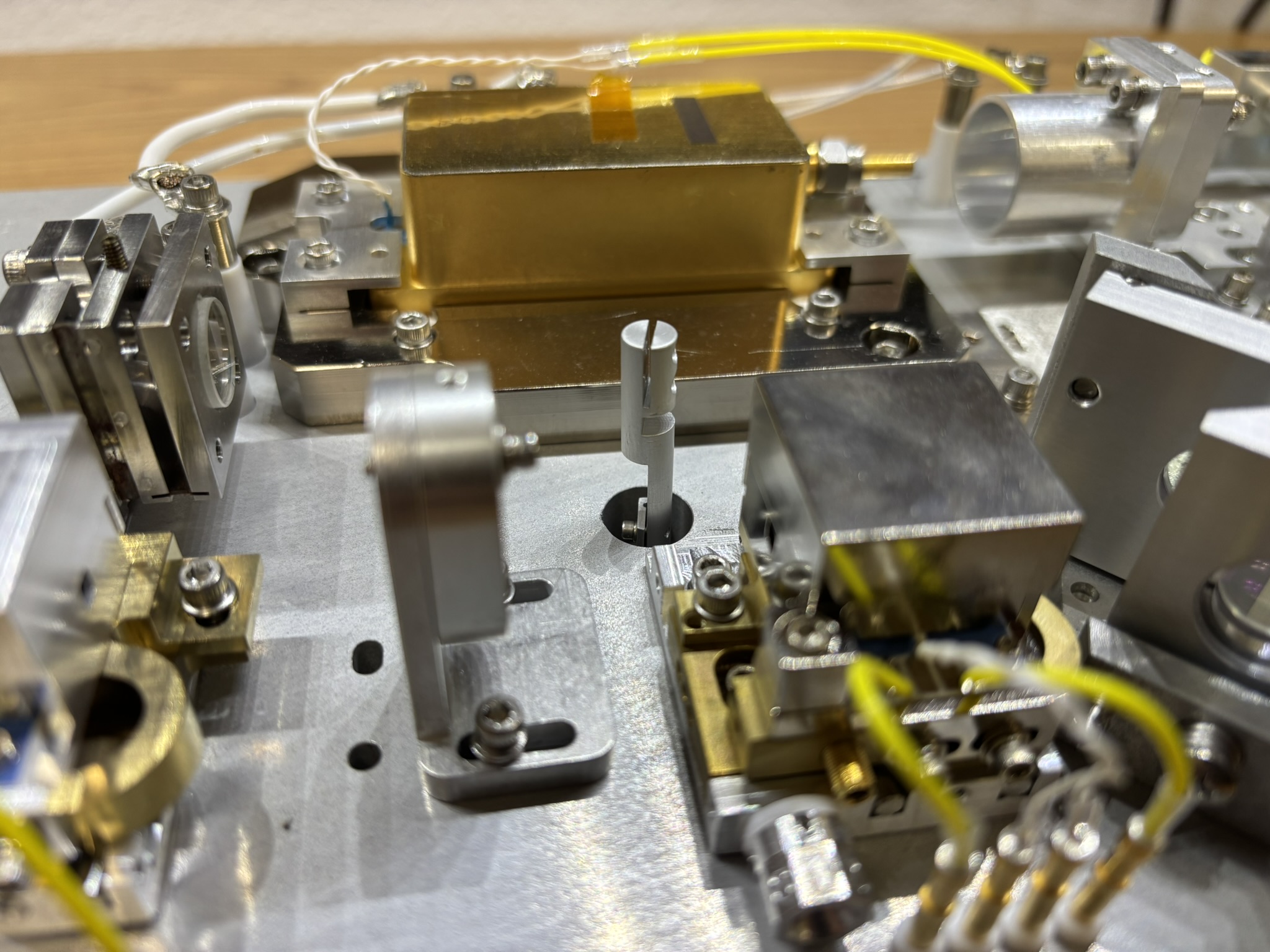

The following 4 images are of our Jasper unit's resonant cavity. Several components are missing, so we have included an image of a complete Jasper resonant cavity lower on this page along with an annotated beam path diagram and a description.

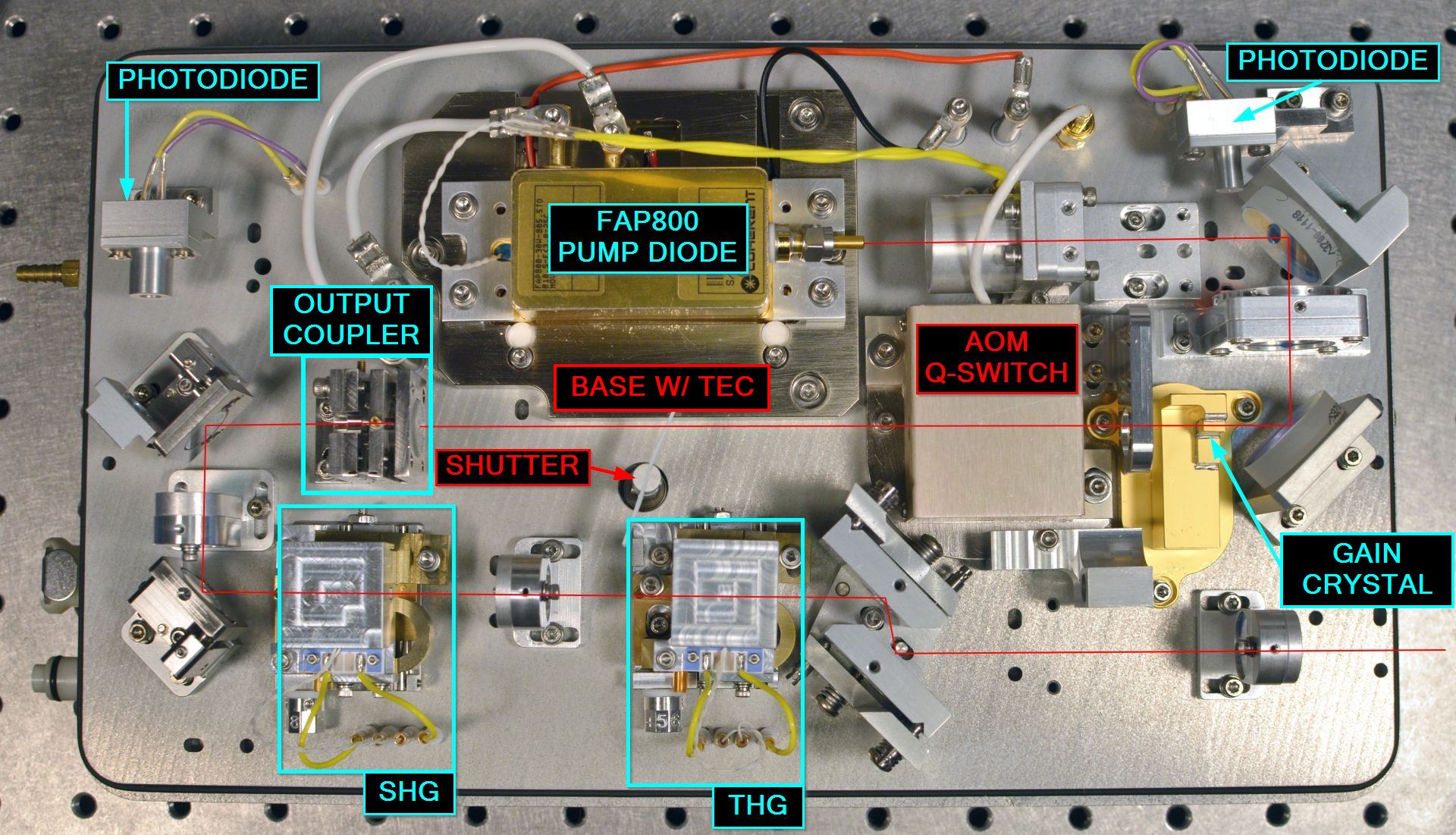

Below is an annotated image of a complete Jasper unit. The beam path is as follows: 808nm laser light is emitted by a Coherent FAP800 pump diode bar. Light exits as a free space beam and continues through a condensing lens and then bounces off a mirror. There is a photodiode located above the mirror to measure the pump diode power. Light then passes through an optic, bounces off another mirror, and then through a Nd:YVO4 (neodymium-doped yttrium orthovanadate) gain crystal mounted to the gold carrier. When 808nm laser light enters the Nd:YAG crystal, 1064nm light is emitted. After the Nd:YAG crystal, laser light passes through an acoustic-optic modulator or q-switch. The q-switch is used to generate high power pulses of laser light. A shutter can interrupt the beam path after the q-switch if required. 1064nm laser light then passes through the output coupler, reflects off a mirror, passes through another optic, and the reflects off another mirror, essentially making a u-turn. Next is the SHG (second harmonic generation) crystal, likely LBO (lithium triborate) or KTP (potassium titanyl phosphate). When the 1064nm laser light passes through the SHG crystal, the frequency is doubled, which divides the wavelength half, resulting in the production of 532nm laser light. Some 1064nm light still remains and continues to the next step. After passing through an optic, 532nm (and some remaining 1064nm) laser light enters the THG (third harmonic generation) crystal which is likely LBO (lithium triborate). Within this crystal, frequency summation takes place, mixing the 1064nm and 532nm beams, resulting in the production of 355nm laser light. Lastly, the beam gets translated down a bit by the opposing set of mirrors and then through the final output coupler as 355nm laser light. Additional optics following the THG crystal likely filter out any remaining 1064nm or 532nm laser light before it exits the system. The Jasper uses a linear beam path arrangement, rather than a folded cavity arrangement.

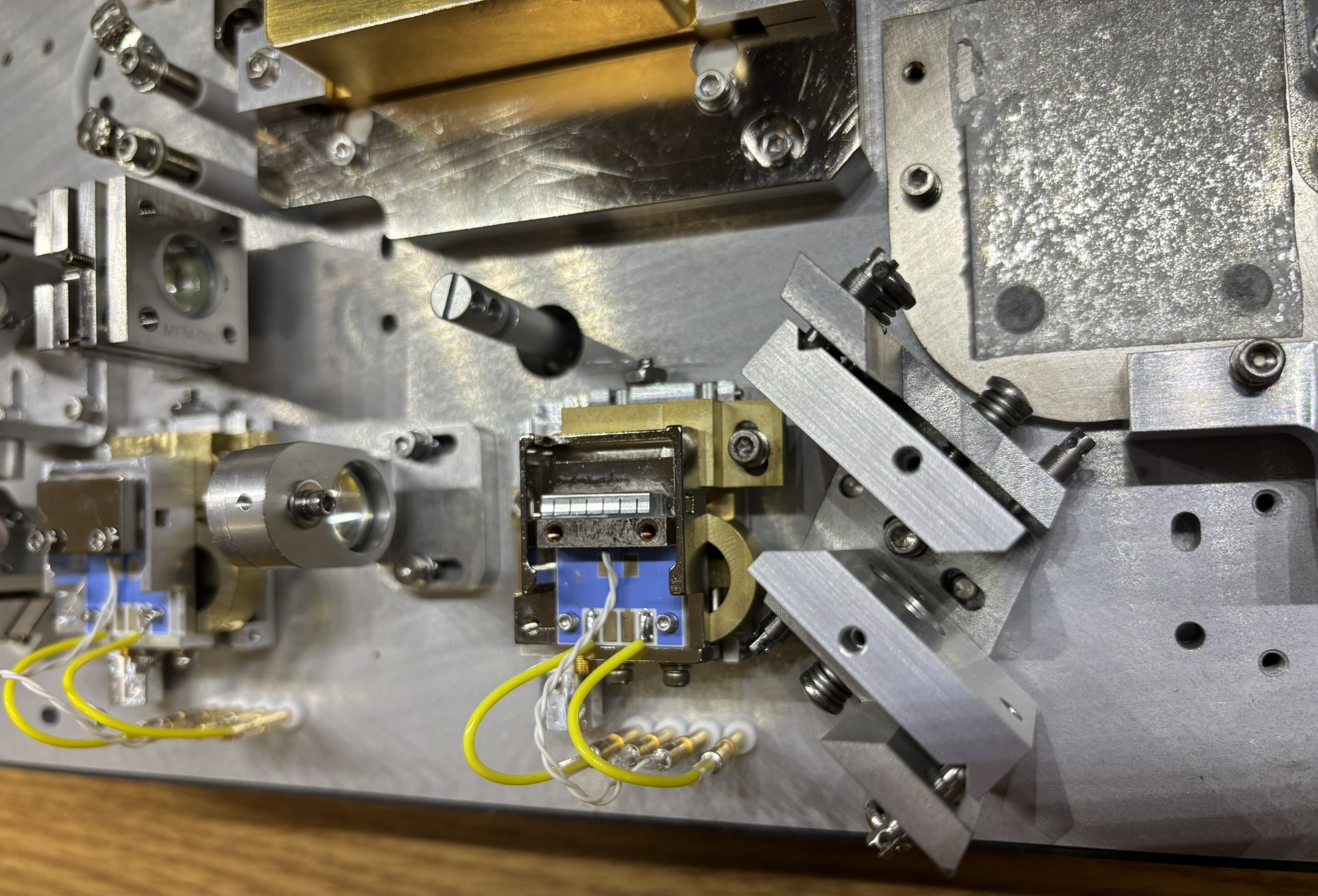

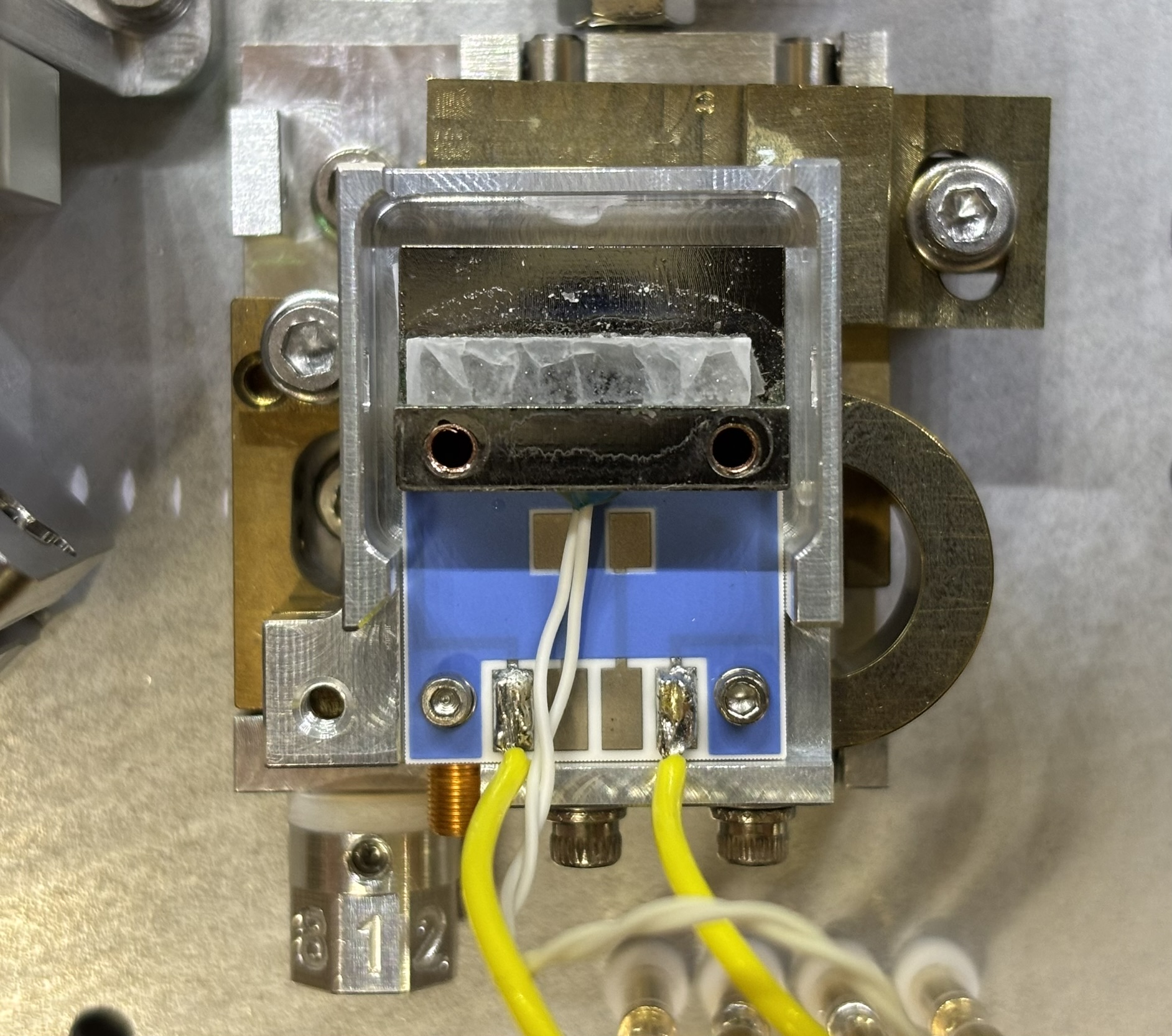

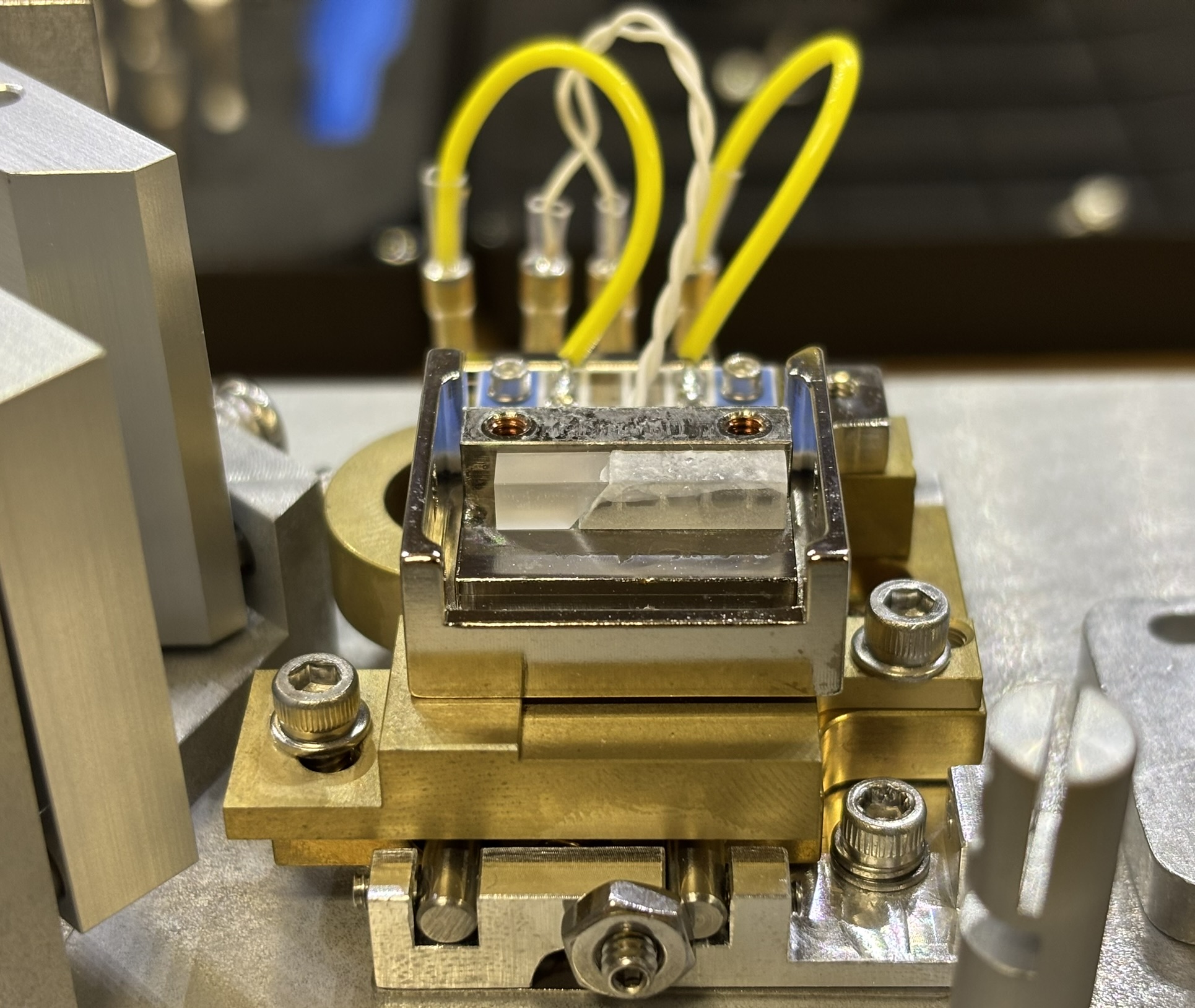

Removing the outer and inner crystal covers reveals the actual THG crystal in the picture below. Each crystal is secured in to a holder that is mounted on a PTC heater and respective thermistor to regulate and monitor the temperature. The yellow wires connect the PTC heater pad, and the white wires are for the thermistor. This whole assembly is then mounted on the precision adjustable stage used to translate the position of the crystal as mentioned earlier. As an aside, it's a common misconception that KTP and LBO crystals are hygroscopic (meaning they tend to absorb moisture). KTP and LBO crystals are actually not hygroscopic, although other types of crystals, such as BBO (barium borate), can be.

In the images below, you can see that the crystals in our Jasper have met their demise. This is the SHG crystal, and it looks like it has absorbed moisture and caused many fractures throughout the crystal. This is perplexing because we mentioned that KTP and LBO crystals are not normally hygroscopic. Either this is actually a different type of crystal or it's an edge case of moisture damage. Also, it is possible that the crystals were clamped too tightly or the casing was subjected to a significant shock.

This is the THG crystal assembly, which actually seems to be made up of two individual crystals placed next to each other. One crystal appears to be perfectly fine, while the other is heavily degraded much like the SHG crystal. At the end of the day, we're not entirely sure what happened to these crystals, but they are definitely destroyed and are no longer usable.

In the center of the picture below is the shutter shaft with the actual shutter material missing. The shaft is connected to a small motor that rotates 90 degrees and snaps back to the closed (beam blocked) position. From examining the images of the complete Jasper system, the shutter looks to be a frosted quartz or glass material rather than an opaque piece of metal. This is likely to diffuse the beam rather than just block it due to the high power level generated by the pump diode.

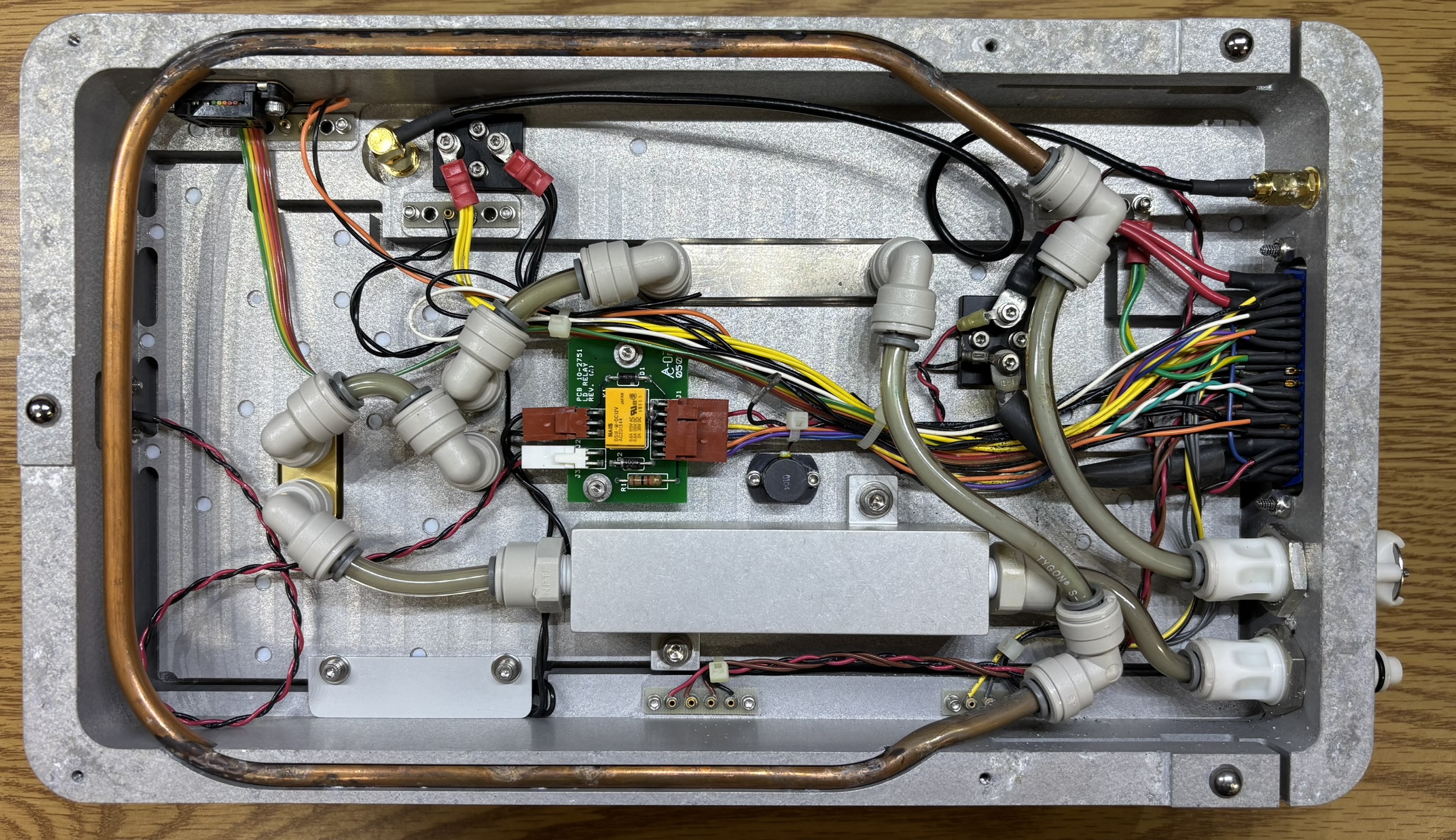

Removing the bottom cover reveals the connections and water cooling tubes within the laser head. The water cooling loop is made up of a copper tube that is pressed into the perimeter of the aluminum casing and several individually cooled sections that included the pump diode. There may also be a filter in series with the cooling loop (rectangular metal block mounted to the underside). There are multiple low current and high current feed through connectors for the components on the other side. The shutter motor is mounted from this side and extends through the middle section of the casing. The small PCB contains a relay that is used for the interlock circuit. The front emission indicator also connects to this board.

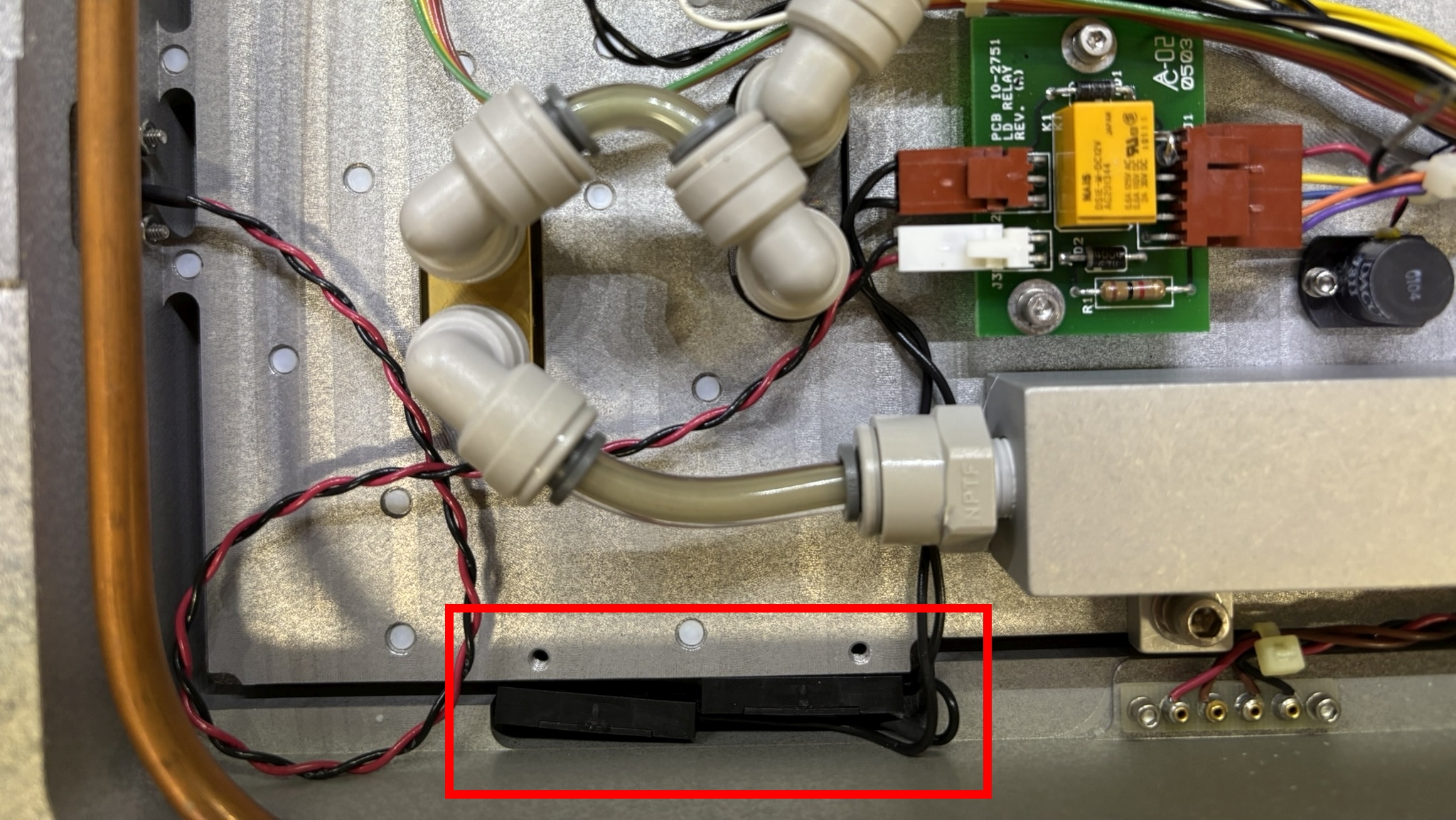

Outlined in red below are two magnetic reed switches wired in parallel. These switches are connected to the interlock board and are used to detect whether the top cover is installed. There is a small neodymium magnet pressed into the top cover which triggers the reed switches. It's strange that there are two reed switches, but since they are wired in parallel, it seems that they wanted to ensure at least one would be reliably triggered when the cover was placed.

We were unable to find much information online about the Jasper other than a brief press release article linked below. Special thanks to Starlight Photonics for sending us this unit to examine, and to Patrick (Zenodilodon) for helping us understand the beam path. Additionally, we have included some links below to learn more about SHG, THG, and nonlinear optics.