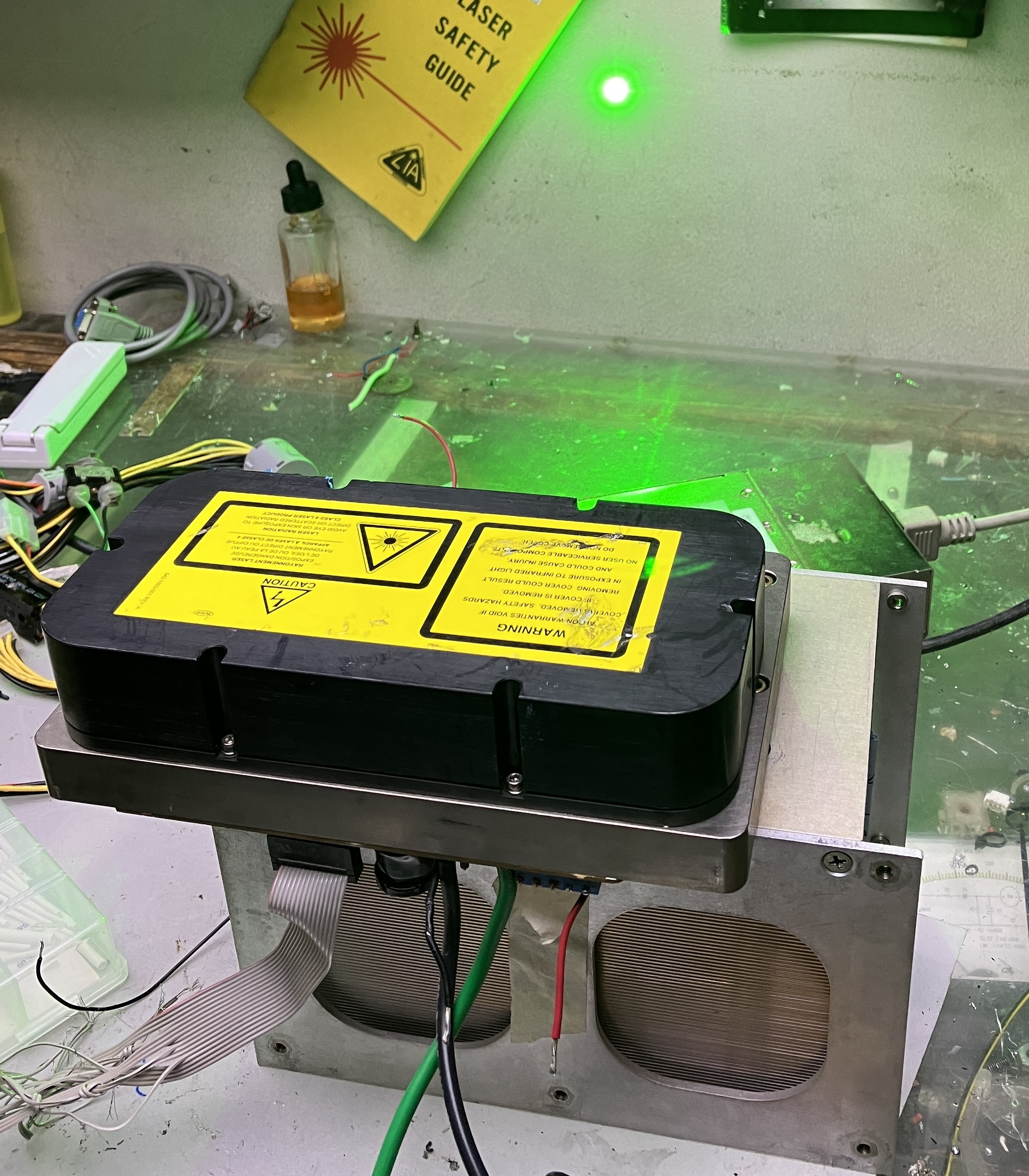

The Lightwave Electronics HalfNote is a 532nm (green) DPSS laser head capable of producing 2.5-3W of laser output power. The history of these lasers is a bit complicated. Lightwave electronics (later acquired by JDSU) originally developed the "HalfNote" 532nm laser head for an ophthalmic laser system manufactured by Alcon, called the OPHTHALAS 532 EYELITE. This ophthalmic laser system was used for laser photocoagulation, which is a type laser eye surgery. It is suspected that Lightwave Electronics sold excess inventory of the HalfNote laser heads under the product title "LWE-246" after their contract with Alcon was terminated. Lightwave electronics also produced other 532nm DPSS lasers at the time that were very similar to the HalfNote, such as the model 244. The HalfNote originally came mounted to a large heatsink with a TEC and a couple of fans. It also had a relatively complicated controller and driver board attached to the side of the heatsink.

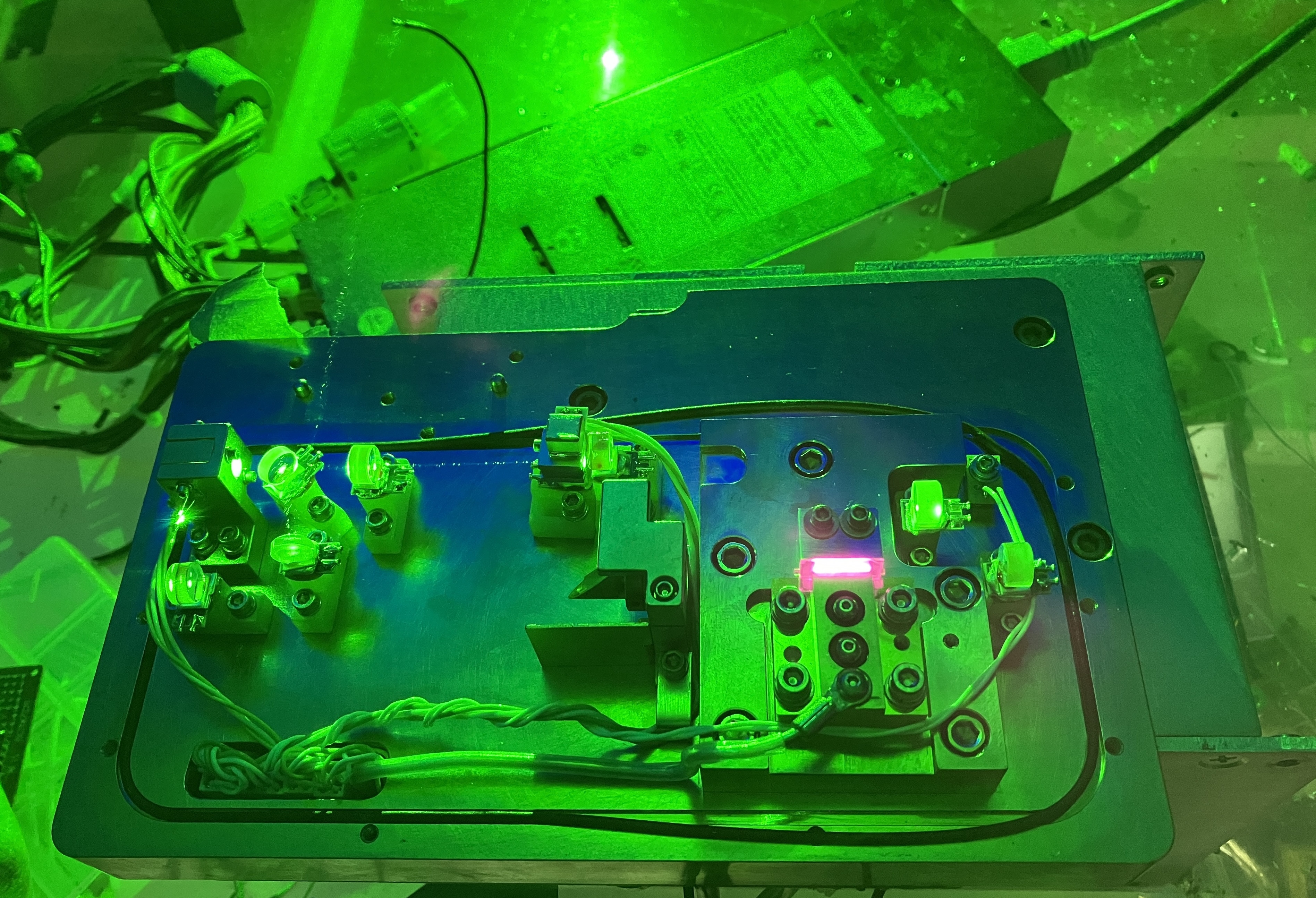

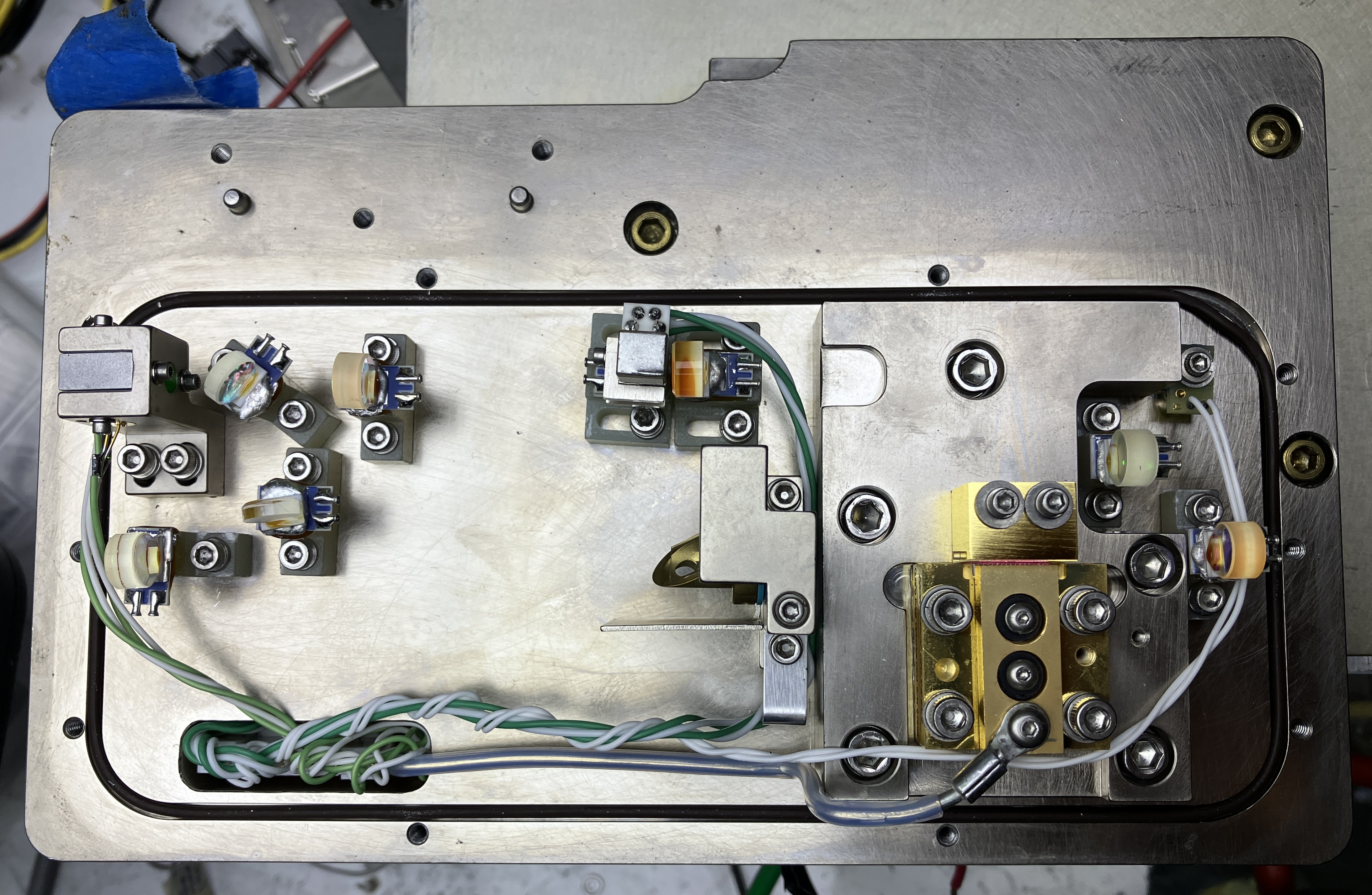

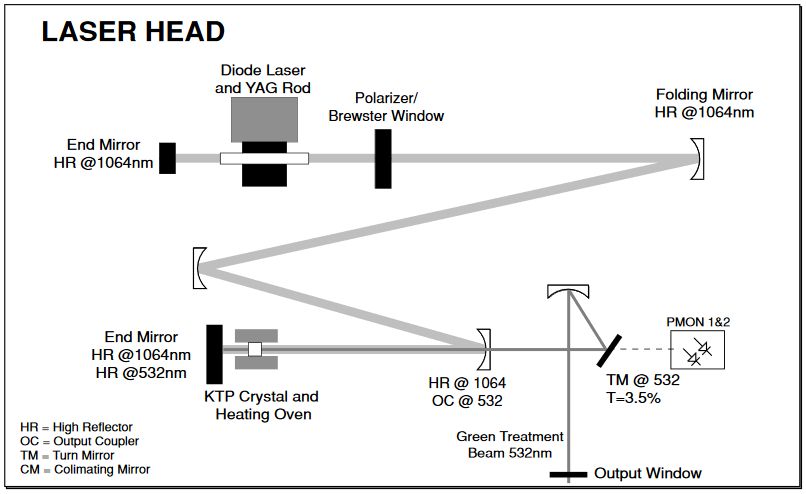

A bar-style pump diode array generates around 20W of 808nm infrared laser light. A Nd:YAG (neodymium-doped yttrium aluminum garnet) rod is placed directly in front of the diode array and is side-pumped by the 808nm light emitted from the array. 1064nm laser light is generated by the pumped Nd:YAG rod and emitted from both sides. A HR (high reflector) directs the beam into the next stage of the optical path. A KTP (potassium titanyl phosphate) frequency-doubling crystal is placed in the beam path between a couple of additional mirrors. The temperature of this crystal is precisely controlled and monitored to ensure optimal performance. The beam interacting with this crystal results in a process called second harmonic generation. During the SHG process, the frequency is doubled which results in the wavelength being divided in half. Therefore, the 1064nm IR light is turned into 532nm (green) laser light. The 532nm light passes through an output coupler and a high reflector that reflects all IR light back into the laser cavity, resulting in a powerful beam of 532nm laser light exiting from the system. The output of the HalfNote was originally fiber-coupled within the OEM product for safe and controlled delivery to the patient. It is worth noting that diode replacements in this laser head are significantly more straightforward than with most DPSS lasers, as optical re-alignment is not necessary. Additionally, the optics within the laser head are secured onto individual pedestals using a low temperature solder. When the correct amount of current is supplied to the two input pins on the pedestal, the solder will melt and become malleable, allowing for adjustment of the optic. Once the proper alignment is achieved, power is removed and the solder quickly solidifies. This is a very unique system for optical alignment, and is more serviceable than glue.

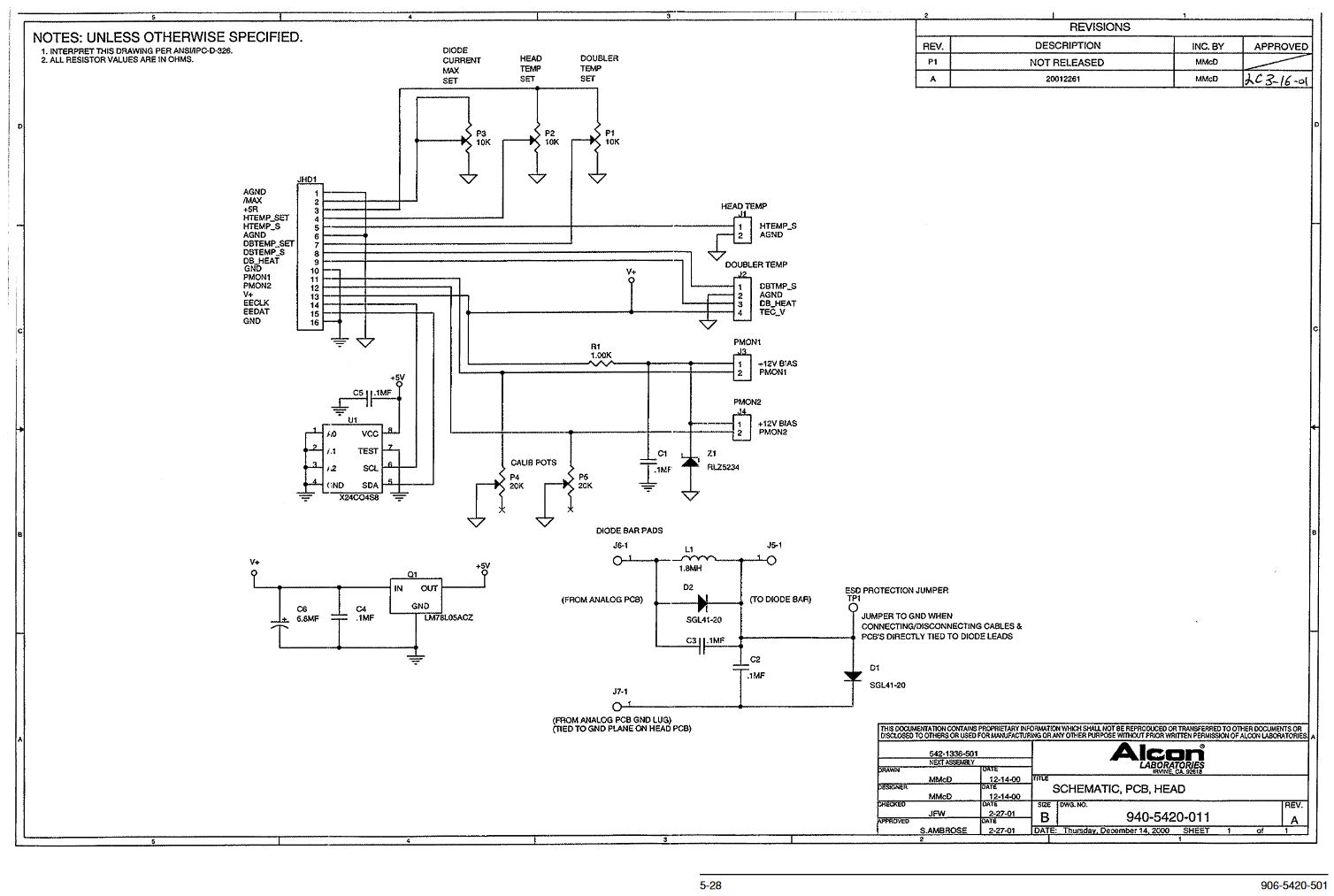

Surprisingly, there is plenty of detailed information about this laser head including schematics for the control boards and pin-outs for the laser head connection in the service manual for the Alcon OPTHALAS 532 EYELITE system. It is quite uncommon to find such detailed service information for a piece of equipment like this publicly available. The following image is a screenshot of the laser head connection pin-out that was taken directly from the service manual. Please visit the link at the bottom of this page to view the service manual as a PDF and learn more about this laser system!