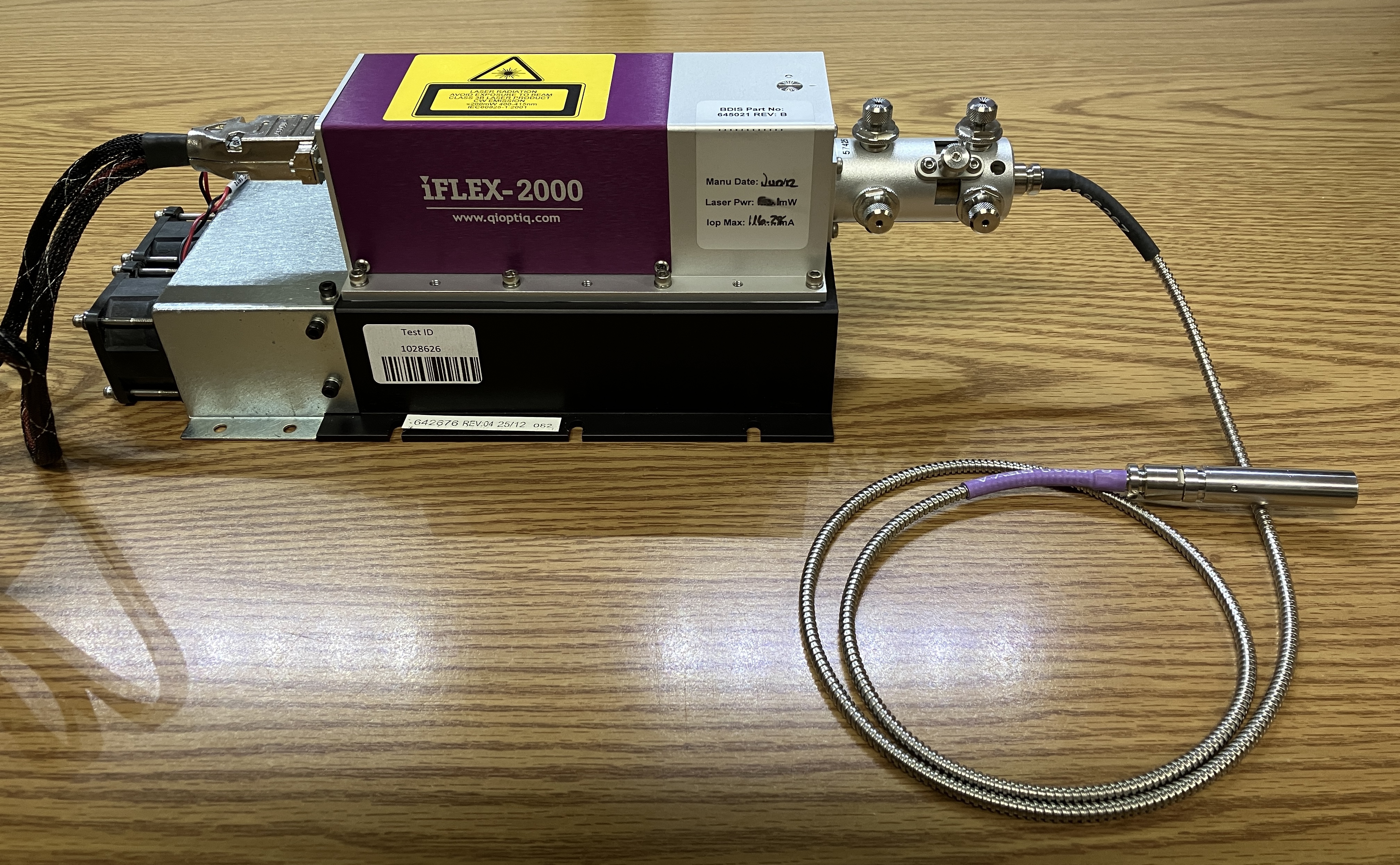

The iFLEX-2000 is a direct-diode laser system originally manufactured by Point-Source, which was later acquired by Qioptiq, which has since been acquired by Excelitas Technologies. The iFLEX-2000 shares some characteristics with the Coherent CUBE lasers, including overall design and form factor. Also, the iFLEX-2000 has a similar internal, closed-loop control system for monitoring and controlling laser output and diode temperature with an integrated TEC. However, the iFLEX-2000 takes a more analog approach to driving and controlling the laser diode. It lacks the digital control and serial interface included with the Coherent CUBE lasers. The iFLEX-iRIS system from Qioptiq is more similar to the Coherent CUBE and OBIS lasers as it includes a digital control interface via USB or RS-232. This iFLEX-2000 laser came mounted to an aluminum heatsink with two fans. It also came with a kineFLEX fiber coupling attachment as well a metal-jacketed fiber cable. The kineFLEX fiber attachment unit has several screws that allow for fine adjustment and alignment of the fiber cable. It also has a quick release button to easily remove and re-insert the jacketed fiber cable. Collimators can be attached to the metal shrouds at either end of the cable. The metal jacket allows for a reasonable amount of flexibility while protecting the delicate fiber from damage. The kineFLEX mount is attached to the front of the laser head with 4 screws.

The power and interface cable included with this laser had two connections, one marked for a power supply board and another marked for a fluidics board. That combined with multiple BD part numbers on the cable and laser head led us to believe that this laser was likely extracted from a piece of laboratory equipment manufactured by BD Biosciences. BD manufactures products such as flow cytometers and sample prep systems. The wavelength of this laser head is in the 405nm range, which is commonly used for flow cytometry. Much like the Coherent CUBE lasers we have purchased, this laser was probably extracted from a flow cytometry system.

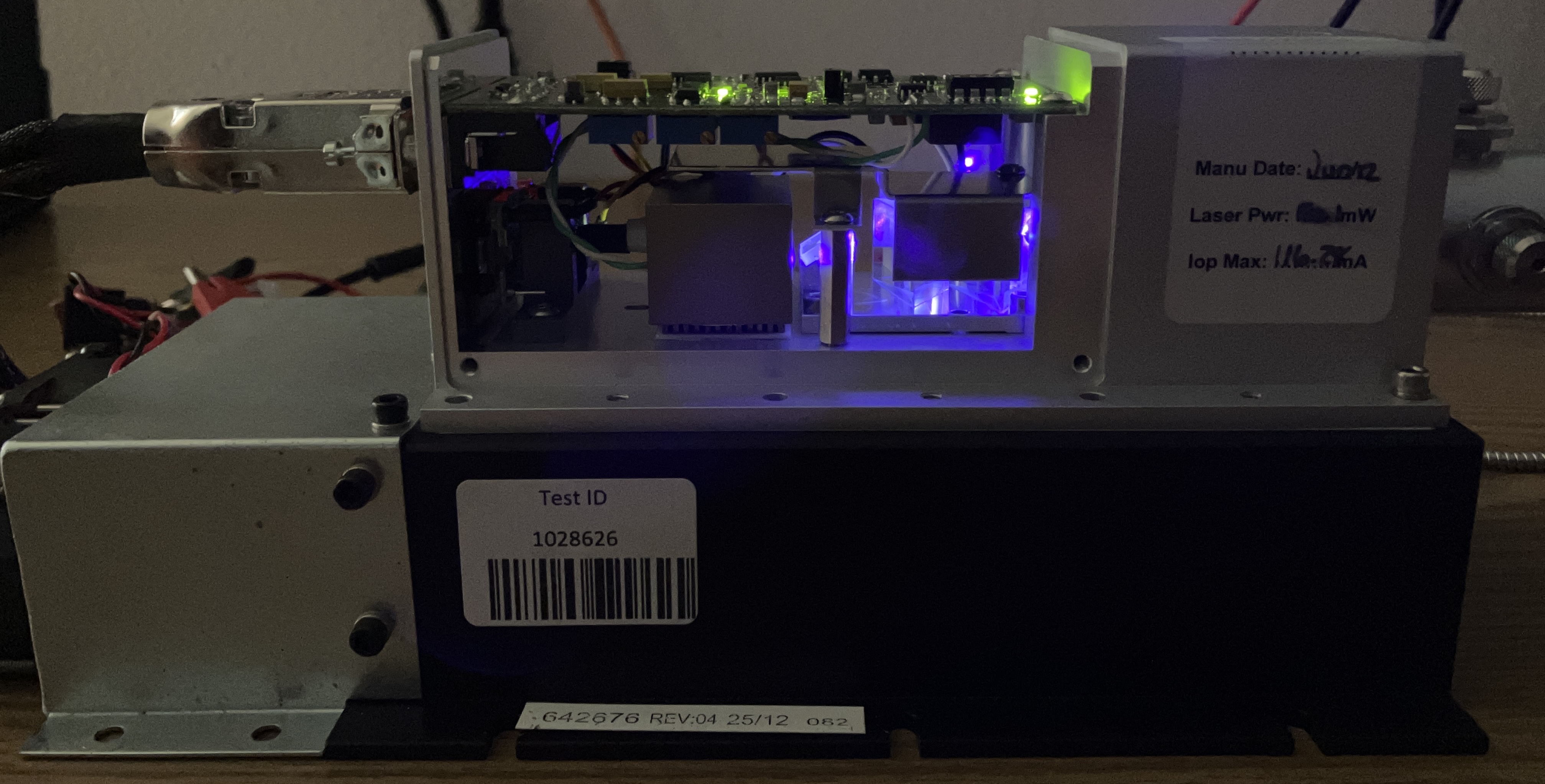

The laser head casing is a solid piece of aluminum that has been milled out very precisely. The small purple cover slides over the outer casing and attaches with screws. This serves as an access panel to the main internal components of the laser. The beam shutter is very similar to a ball valve mechanism, and is opened or closed by a quarter turn of the screw on the top of the laser head. Removing the laser head from its heatsink revealed a very thin, white thermal pad adhered to the bottom. On the back of the unit, there is a DB-9 interface connector, LED indicators for power and emission, and an hour counter. There is also a plug covering the cutout for the modulation connector, which our unit did not come with.

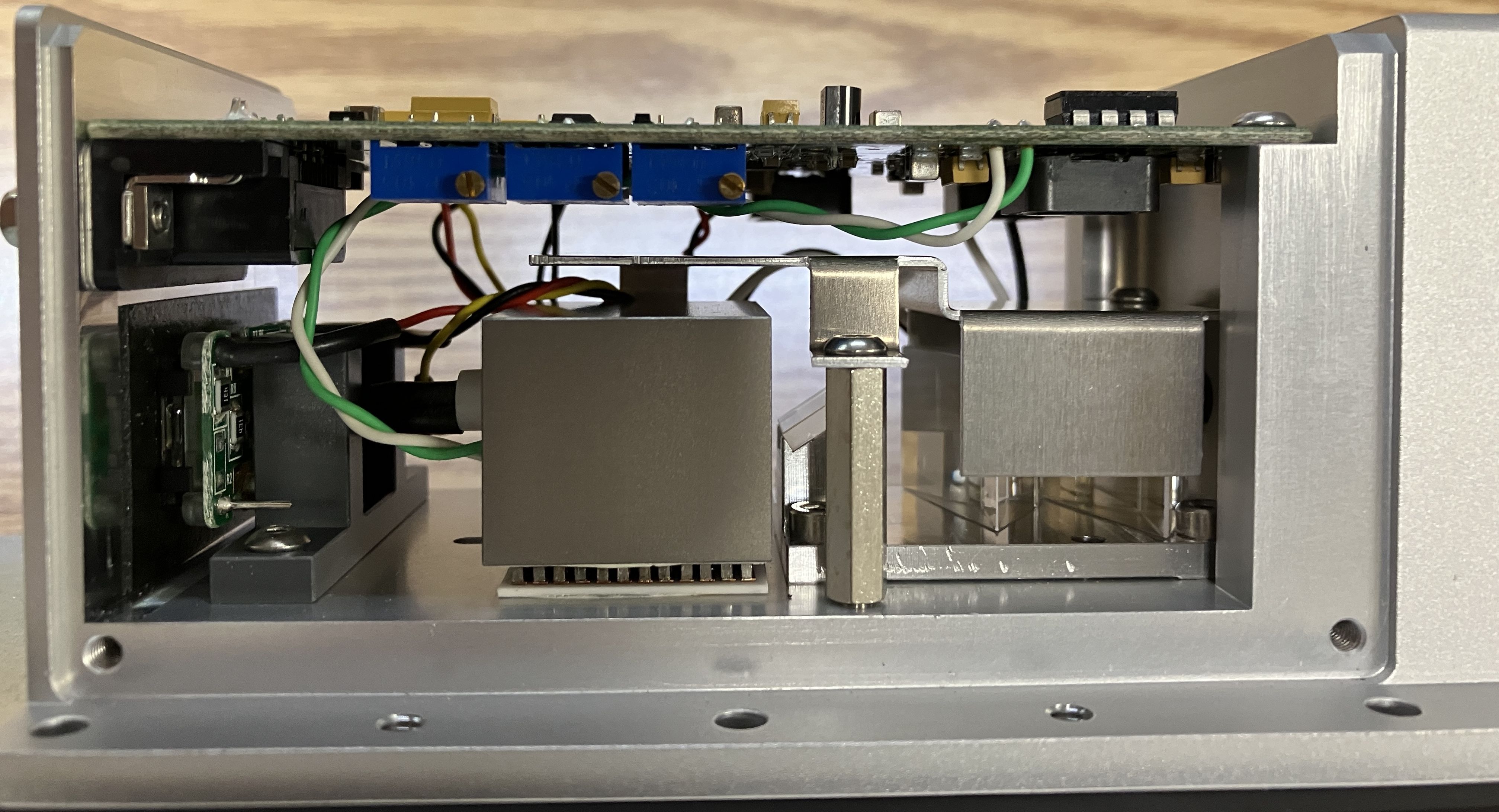

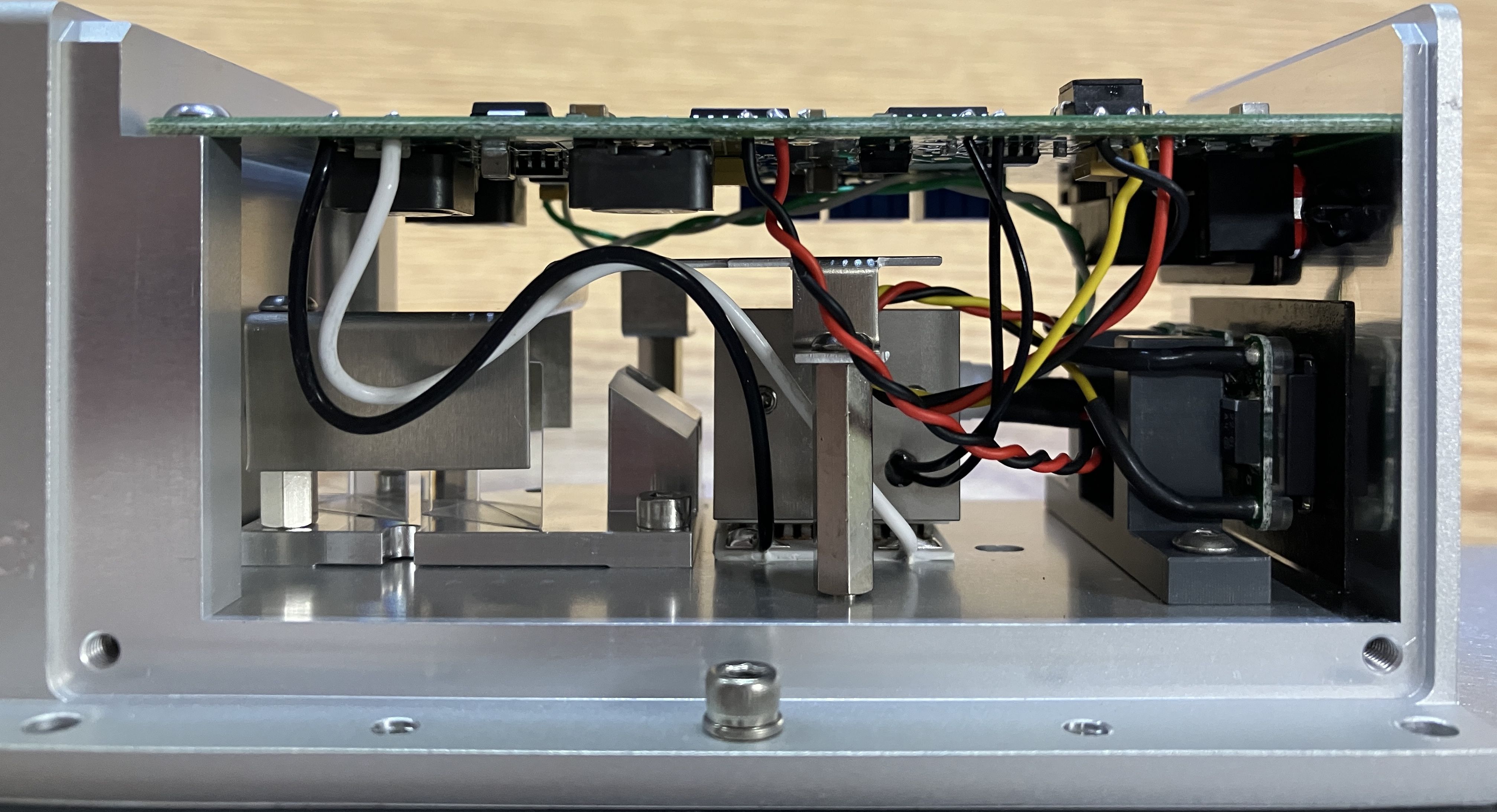

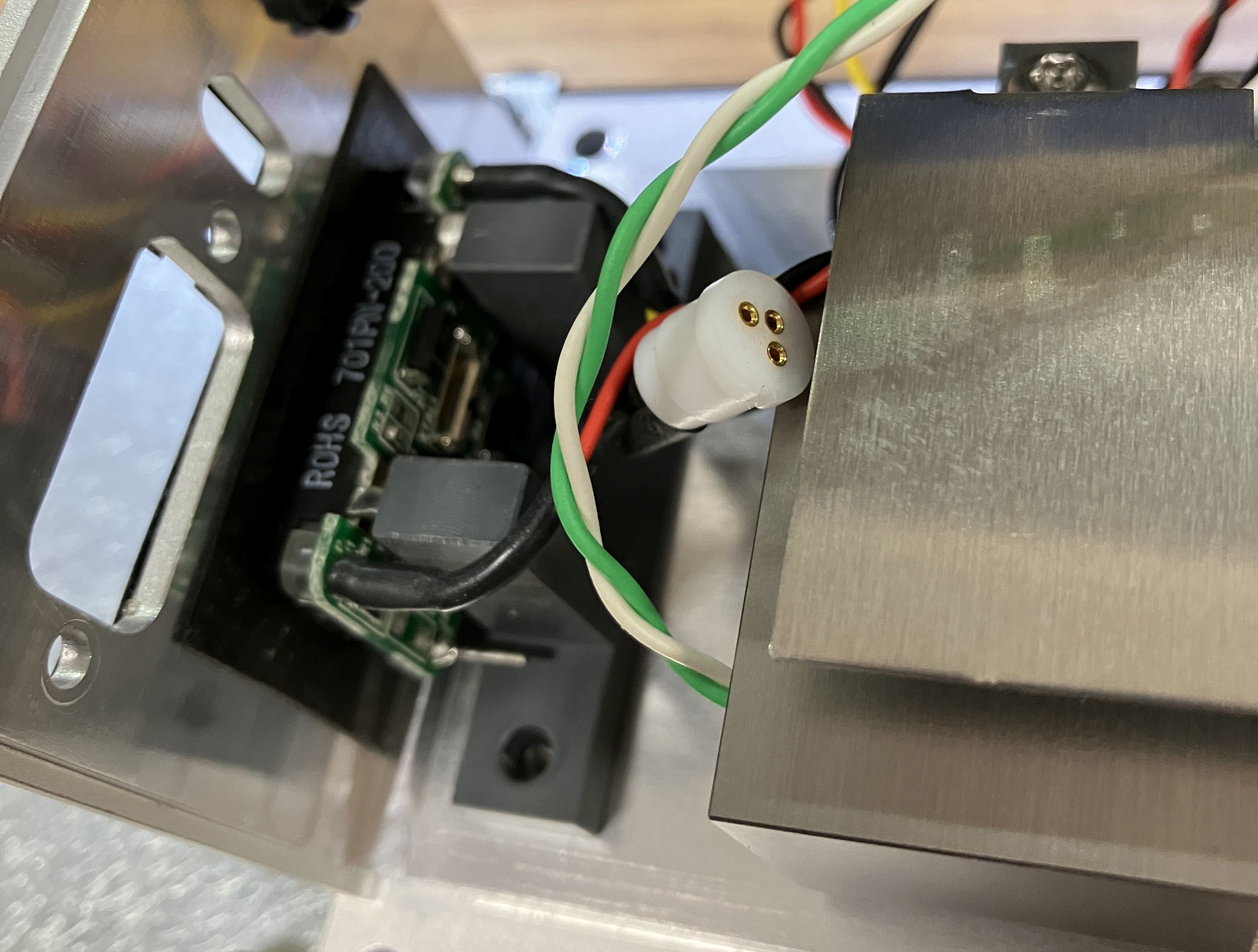

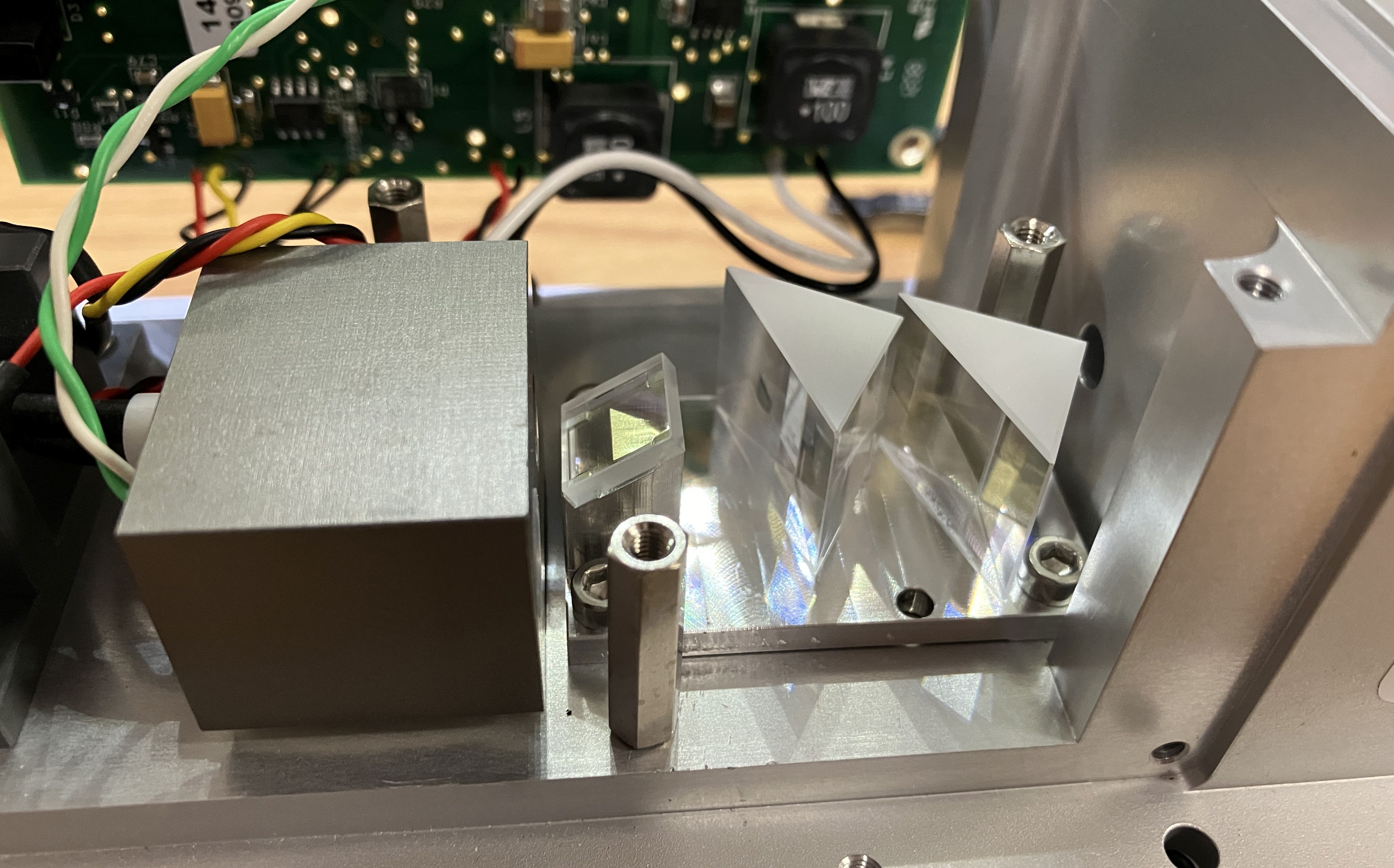

Removal of the access cover reveals the internal components of the iFLEX-2000. The main circuit board is mounted on the top of the unit and secured by the DB-9 connector screws and two screws near the front section of the casing. The hour counter is held to the back side of the case by double-sided tape and a plastic mount pressed up against it and screwed to the bottom of the casing. The laser diode and photo diode are contained within the metal block in the center of the casing which is glued to a TEC, which is glued to the bottom of the case. Next is a separate metal plate containing an unknown optic on a 45 degree angle, and the anamorphic prism pairs for beam correction. The glass optics are protected by a metal plate that is fastened to some standoffs and folded to cover most of the sensitive optical components. It's a very similar design to the Coherent CUBE, just a bit oversized. The anamorphic prism pairs in the iFLEX-2000 are nearly 4 times the size as the ones used in the CUBE.

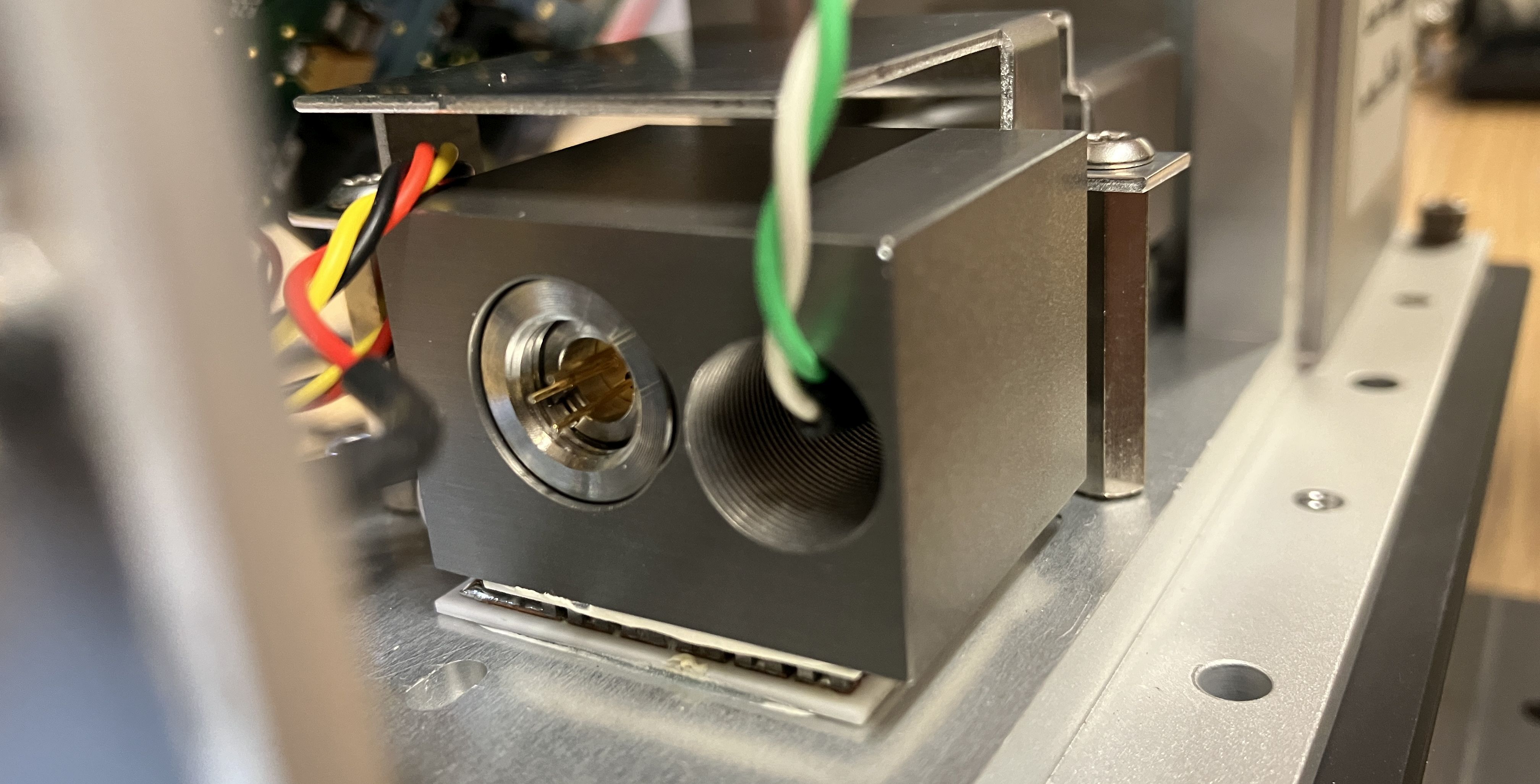

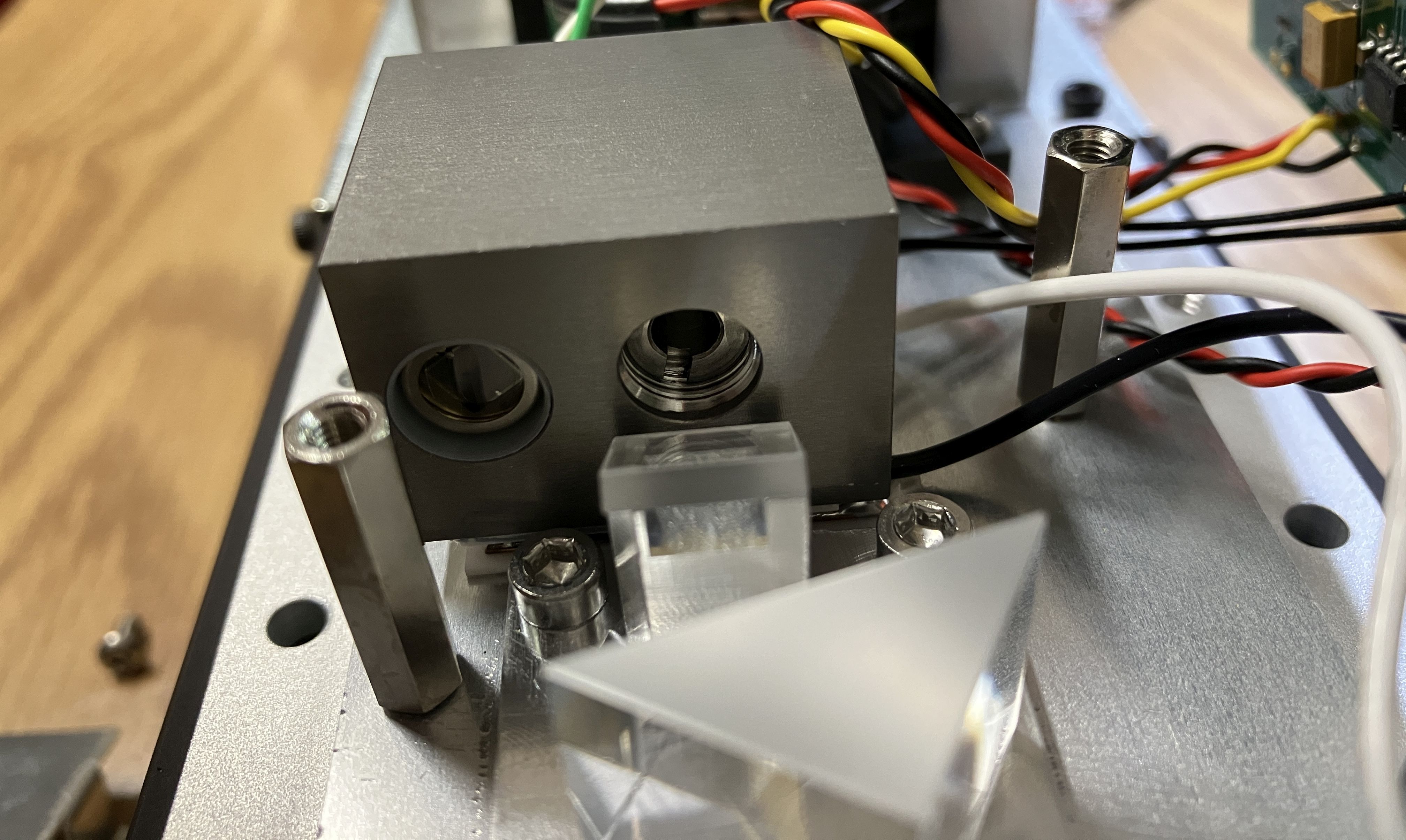

Taking a closer look at the thermally-controlled diode block, we can see that a diode plug is used to connect the 405nm laser diode to the circuit board. This is really nice to see, especially when compared to the CUBE, which has an annoying flat-flex ribbon cable soldered directly to the diode pins. The laser diode and photo diode are each installed in their own threaded openings and are recessed deep into the block. It was hard to see, but we expect that there is a collimating lens installed in front of the laser diode in the threaded opening. The front of the photo diode is just open and faces the edge of one of the anamorphic prisms. We initially expected diode replacements to be very straightforward due to the use of a diode plug, but this is not the case. The diode mounting block being glued to the TEC (which is glued to the case) makes it extremely hard to access the threaded openings for the diodes. Additionally, the hour counter and non-removable back panel prevent easy access to the back of the mounting block when left in place. The only option aside from removing the hour counter and mutilating the back case, would be to separate the diode block from the TEC by dissolving the glue. This could easily damage the TEC and would require re-gluing and re-aligning the diode block, neither of which are ideal.

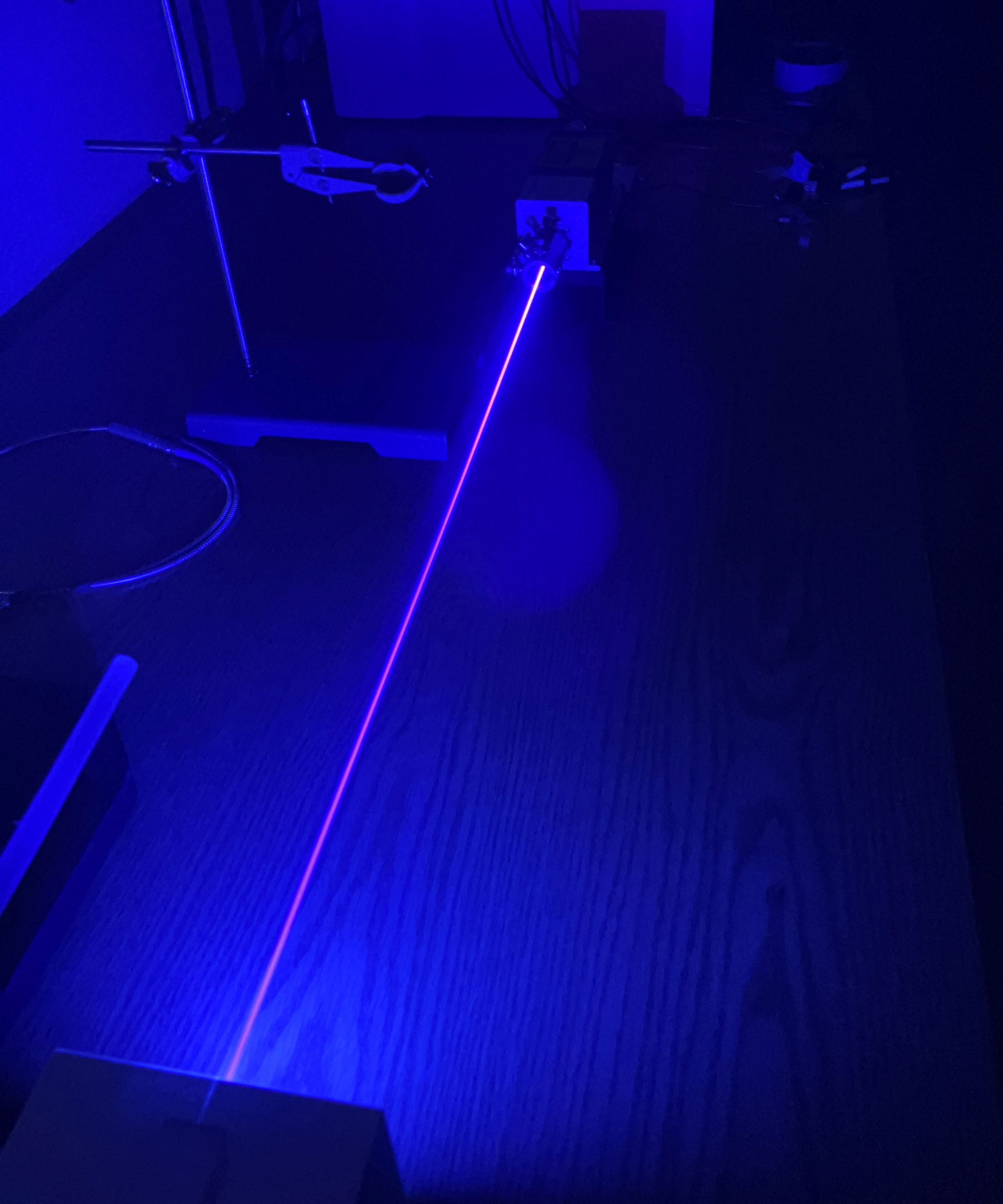

Powering on this laser system was pretty simple, it's not as complex as the digitally controlled laser systems we are used to. All you need to do is supply the required 12V for the laser driver circuit, 5V for the temperature controller circuit, and a 5V laser enable signal and the system should start producing light output. The datasheet for the iFLEX-2000 is readily available and includes the pin-out for the DB-9 connector on the back of the laser head. We have included the pin-out below as well for reference. We assembled a simple external controller for this laser that includes basic controls and connections for monitoring the system and is also compatible with other iFLEX-2000 units.

| DB-9 PIN | FUNCTION |

|---|---|

| 1 | +5V TEC |

| 2 | +12V DIODE DRIVER |

| 3 | +5V LASER ENABLE |

| 4 | TEMP OK (HIGH = TEMP LOCKED) |

| 5 | EXTERNAL CURRENT CONTROL (0V = FULL ON | 5V = FULL OFF) |

| 6 | 0V TEC GROUND |

| 7 | 0V DIODE DRIVER GROUND |

| 8 | DIODE CURRENT MONITOR (10mV/mA) |

| 9 | MONITOR PHOTODIODE (UNCALIBRATED) |

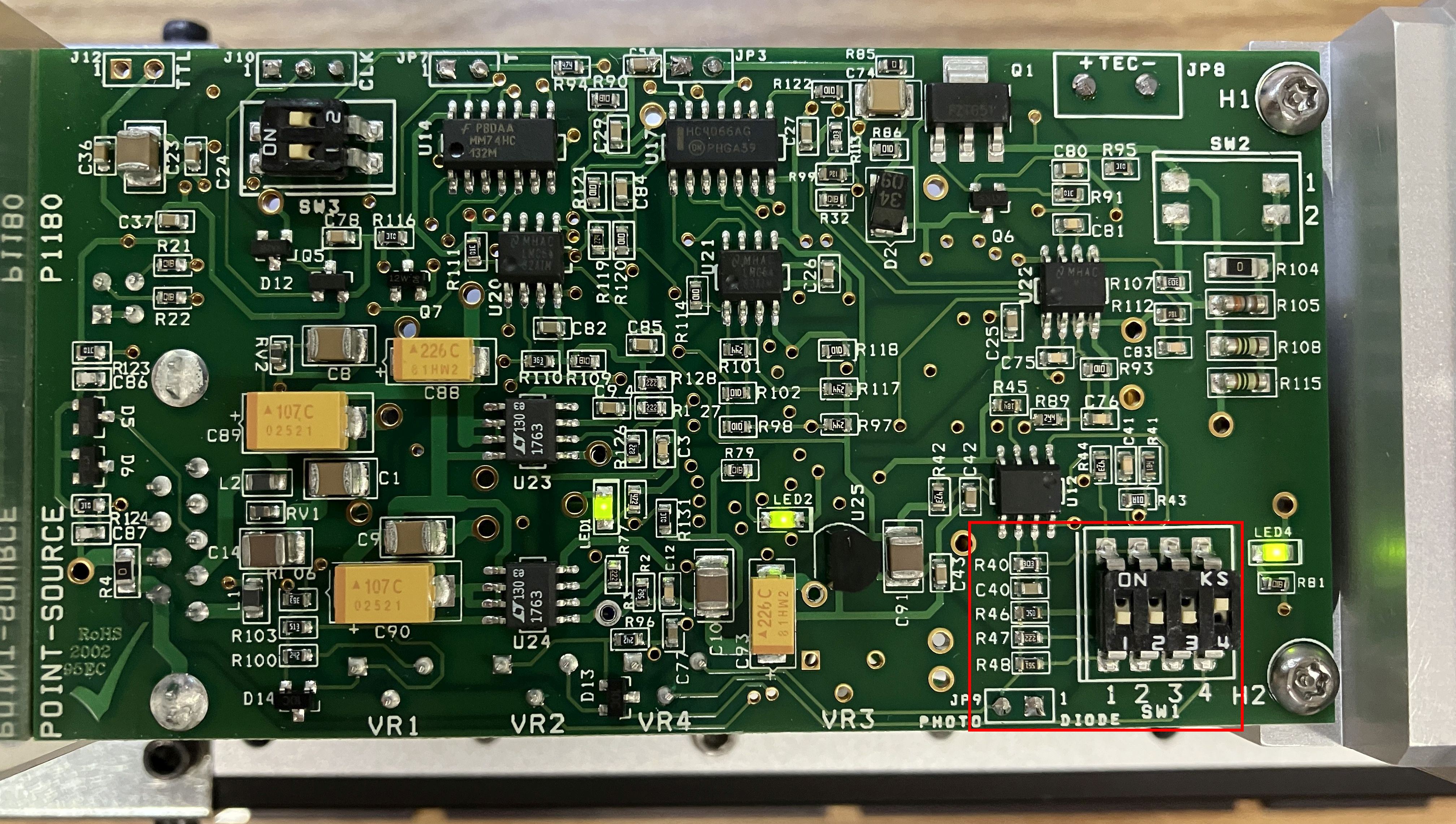

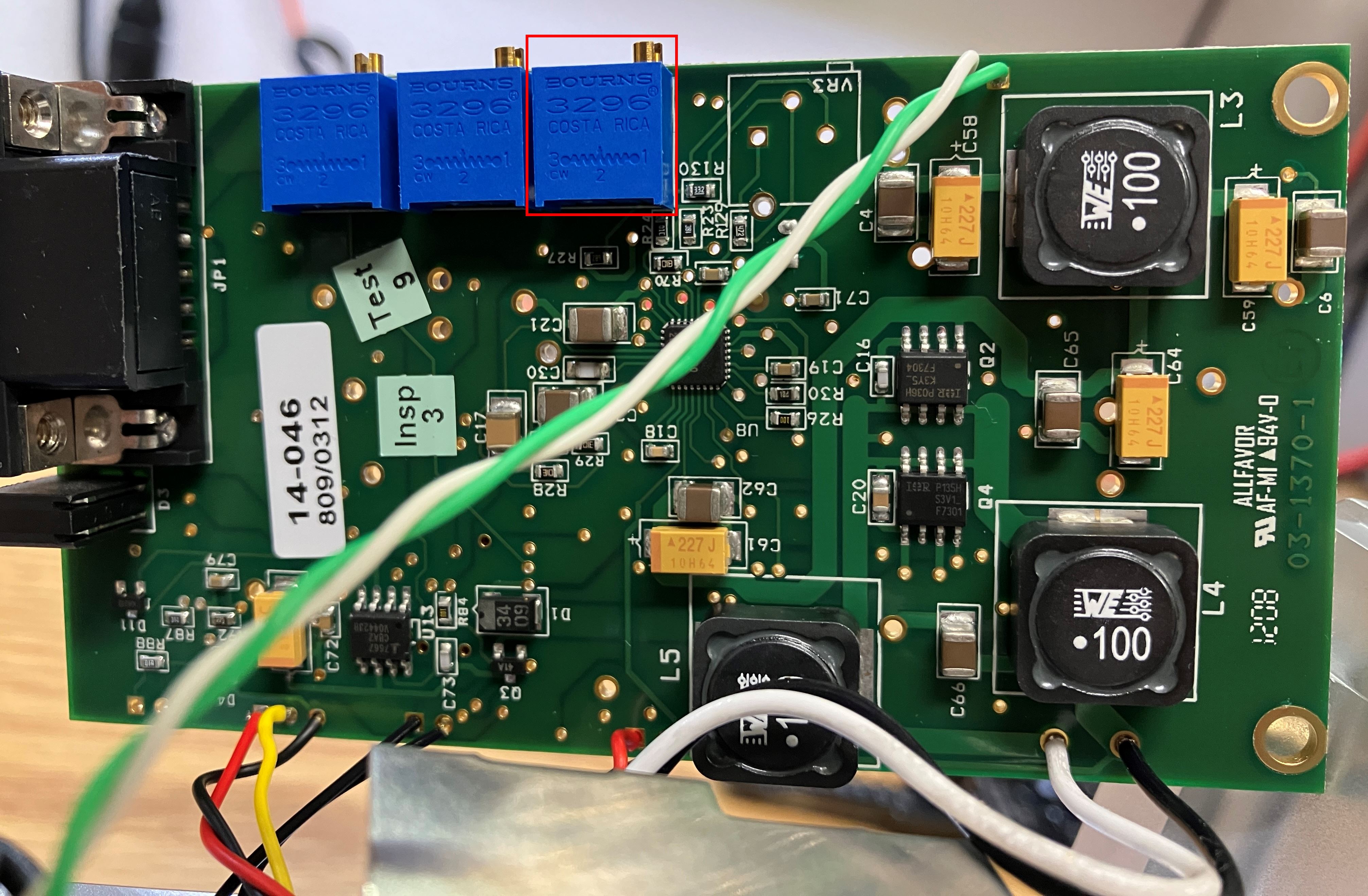

The iFLEX-2000 circuit board is relatively straightforward. It includes a laser diode driver circuit and an ADN8830 TEC driver chip. There are 3 potentiometers on the board as well as a few banks of DIP switches. We identified one bank of 4 DIP switches (SW1) which is used to switch in constant resistor values, which in turn controls the diode current. The potentiometer outlined in the picture (VR4) is also used for diode current control and is put into circuit by turning DIP switch number 4 (in the SW1 package) on. The DIP switches are essentially used for "coarse" diode current control, and the potentiometer is used for "fine" current control. DIP switches 1-3 are connected to SMD resistors next to the package, each switch enables a different resistor value. They can be combined to achieve a wide resistance range especially when using the potentiometer as well. It is important to note that the current control works backwards in this circuit, meaning as the resistance increases on the potentiometer and DIP switches, the diode current increases as well. Turning the potentiometer clockwise decreases the resistance and diode current, turning it counter-clockwise increases the resistance and diode current. Keep this in mind when working with the iFLEX-2000 as laser diodes can be easily damaged by excessive current. We also noticed that the temperature controller circuit is quite sensitive, more so than other temperature-controlled diode lasers we have worked with. The output will stop while the temperature stabilizes, and comes back on usually within 30 seconds.

Overall, the iFLEX-2000 is an extremely well built, over-engineered, and oversized direct-diode laser system. That combined with the traditional diode current control system indicate that it was probably just an earlier design for an OEM diode laser system. Modern diode laser systems like the Coherent CUBE are much more compact, modular, and can be controlled digitally over a serial interface. The ability to adjust the diode current using the potentiometers and DIP switchers is a huge advantage of the iFLEX-2000. The difficult-to-access diode mounting scheme is the only significant limiting factor of the iFLEX-2000 when it comes to repairs and aftermarket uses or modifications.