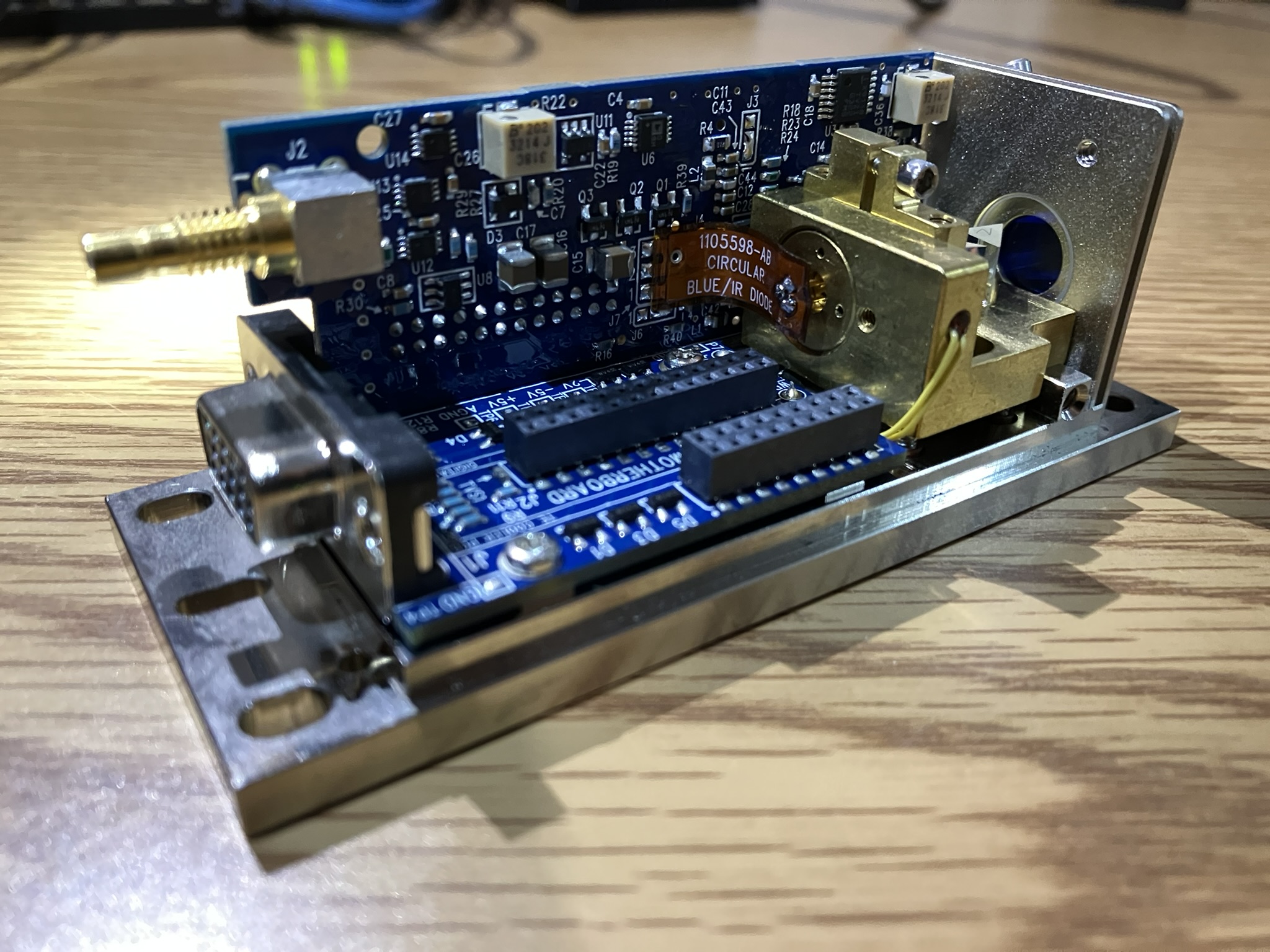

This laser head was purchased online in working but low power condition. We were able to successfully repair this unit by performing a diode replacement. It is manufactured by Coherent and is of the CUBE product series. They are marketed as plug-and-play laser systems for OEM integration and lab use. They are designed to be very easy to use and integrate as the laser head contains a closed-loop monitoring and temperature control system. All of the electronics required to ensure optimal laser operation, including thermoelectric coolers and temperature sensors, are contained within the head and controlled by a microprocessor. This is desirable as the OEM or operator of the laser system does not need to worry about the operating conditions and monitoring of the laser head. The unit can be controlled digitally by RS-232 or USB (which is just a built-in USB to serial converter). The unit can also be controlled and modulated in an analog manner by using the SMB connector on the back and connectors on the main interface cable.

This unit was listed as "low-power" because it does work, but was not operating at full manufacturer specification anymore. Testing with the Coherent Connection software indicated a maximum output power of less than 1mW while running at a current significantly higher than the typical operating current (over 200 mA). Light output was just barely visible. Essentially, the original diode within this laser system is spent and is now operating in an over-current condition. This is when a laser diode draws more current than normal while not producing adequate light output. This is common with laser systems that have many power on hours or that have been operated outside of manufacturer specifications. We opened up the casing of the unit and removed the control boards responsible for serial communication and thermal management. The flat-flex cable was de-soldered from the original laser diode and the diode driver board was removed. A small metal ring was unscrewed from the back side of the laser mounting host using a metal drafting compass with two sharp points. An unorthodox tool to use, but it proved to work extremely well. At this point, the diode was extracted and replaced with a Mitsubishi ML101J25 100mW ~660nm laser diode. The diode driver board was replaced and soldered to the new diode followed by the other control boards.

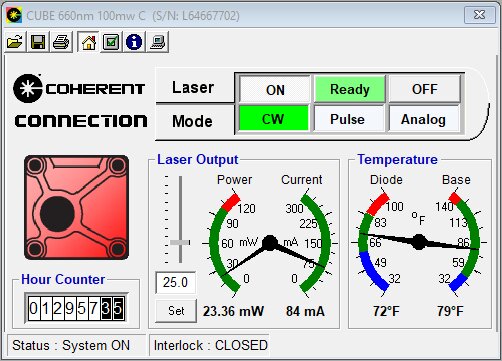

Below is a screenshot of the Coherent Connection software. It communicates with the laser head over RS-232 serial and allows laser monitoring and control. Most aspects of the laser head can be controlled with the software, and the laser head can be completely controlled by serial commands using a program such as PuTTY. Since the repair has been completed, the laser is now working extremely well. The screenshot below shows the output power set to 25mW, the actual output is well within specification and the current is correct. The over-current condition is no longer present. We tested this laser up to 80mW and it performs extremely well. To preserve the life of the diode we do not plan to push it past 80mW and will likely not need to increase the current past 50mW during normal use. Under-driving the diode can help extend its life.

The CUBE laser head has 3 connectors on the back for laser power, monitoring, and control. The small SMB connector is used for analog modulation. The USB connector is a built-in USB to serial interface that provides the same RS-232 control as the RS-232 interface built in to the main DE-15 connector. The DE-15 connector carries power, interlock signals, and RS-232 as well as some other extra inputs and outputs. A connection and control kit is available from Coherent, but this laser head was operated with a custom interface cable fashioned from a DE-15 breakout connector and extra electronics parts.

The front of the laser head has a manually operated beam shutter to prevent laser output when not desired. The color of the anodizing coincides with the wavelength and visible color of the laser beam.

Since being repaired, this laser is working like new!

Coherent does a great job making their software and operator manuals for their products easily accessible. We were able to get this laser up and running so fast due to the accessibility of the manual and software. Links are provided below. The manual contains all of the necessary information to get one of these lasers running including pin-outs and serial commands.