This laser head was purchased online in unknown condition. The photos showed minor wear on the laser head casing and included one photo of the beam. The seller provided no other information so we took a chance purchasing this unit. Luckily it was not a total loss. This laser head is manufactured by Coherent and is of the CUBE product series. They are marketed as plug-and-play laser systems for OEM integration and lab use. They are designed to be very easy to use and integrate as the laser head contains a closed-loop monitoring and temperature control system. All of the electronics required to ensure optimal laser operation, including thermo-electric coolers and temperature sensors, are contained within the head and controlled by a microprocessor. This is desirable as the OEM or operator of the laser system does not need to worry about the operating conditions and monitoring of the laser head. The unit can be controlled digitally by RS-232 or USB (which is just a built-in USB to serial converter). The unit can also be controlled and modulated in an analog manner by using the SMB connector on the back and connectors on the main interface cable.

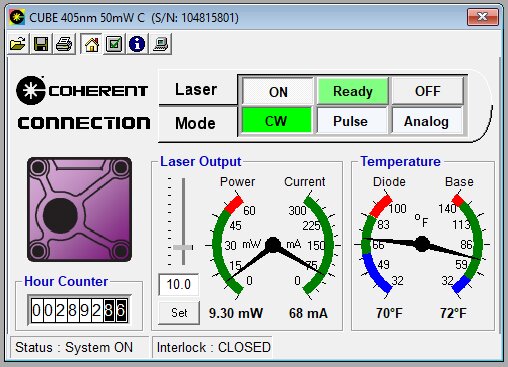

This unit in particular originally fell into the "low-power" condition category because it does work, but cannot operate at full manufacturer specification anymore. Testing with the Coherent Connection software indicates that the laser head output maxes out at around ~13mW, significantly less than the 50mW nominal power rating. This is common with laser systems that have many power on hours or that have been operated outside of manufacturer specifications. This unit in particular has around 2,892 power on hours. However, a diode replacement was performed on this laser and it is now operating well within manufacturer specification. Below is a screenshot of the Coherent Connection software. It communicates with the laser head over RS-232 serial and allows laser monitoring and control. Most aspects of the laser head can be controlled with the software, and the laser head can be completely controlled by serial commands using a program such as PuTTY. The screenshot below shows the power originally being limited to ~10mW, this was being done to preserve what life the laser diode has left and to prevent an over-current condition before the diode replacement was performed. When laser diodes reach the "low-power" status, they will draw more electrical current but provide no additional laser output, this is called an over-current condition. The intelligent monitoring and software displays this error when a serial connection is initiated with the laser head in the form of a fault code of 2048. The laser head does still operate in this condition. This fault went away once the diode was replaced and the laser now outputs 50mW of power. The original diode was replaced with a 405nm Sony SLD3235VF 5.6mm 100mW laser diode.

The CUBE laser head has 3 connectors on the back for laser power, monitoring, and control. The small SMB connector is used for analog modulation. The USB connector is a built-in USB to serial interface that provides the same RS-232 control as the RS-232 interface built in to the main DE-15 connector. The DE-15 connector carries power, interlock signals, and RS-232 as well as some other extra inputs and outputs. A connection and control kit is available from Coherent, but this laser head was operated with a custom interface cable fashioned from a DE-15 breakout connector and extra electronics parts.

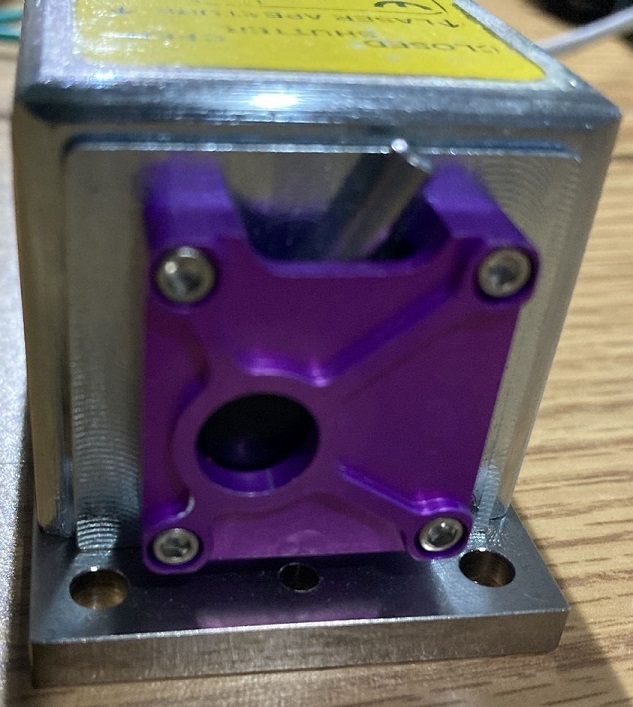

The front of the laser head has a manually operated beam shutter to prevent laser output when not desired. The color of the anodizing coincides with the wavelength and visible color of the laser beam.

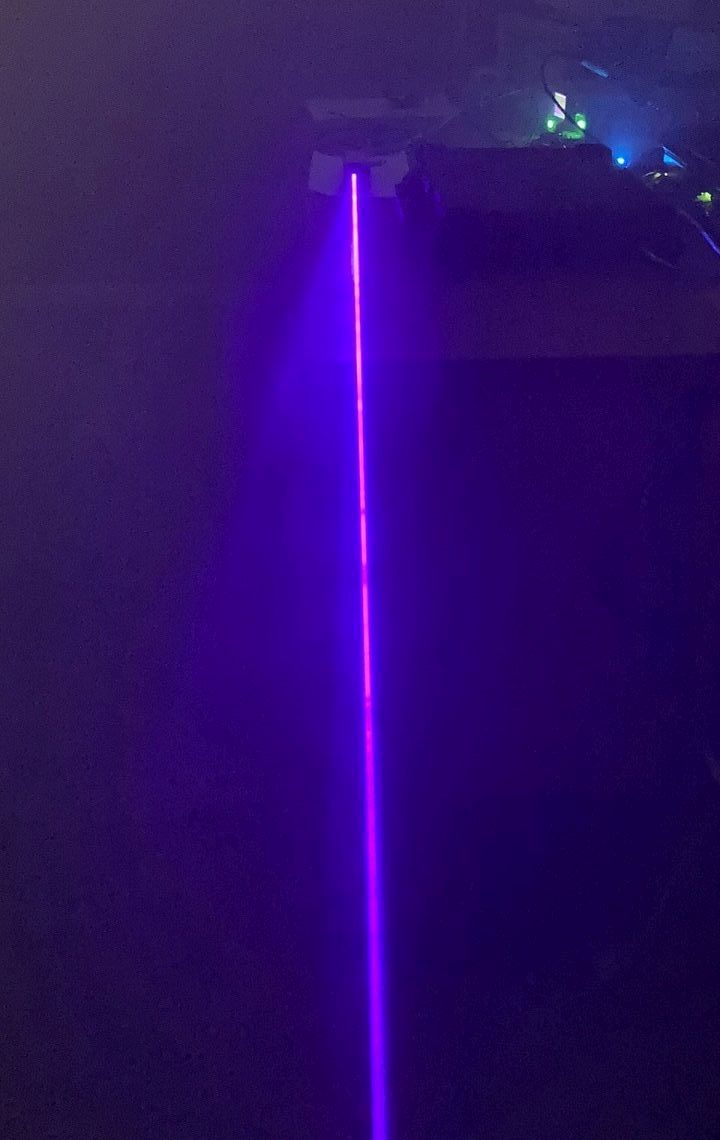

This photo was taken before the diode was replaced. Despite the low-power condition, the beam is still impressive.

Since the diode replacement, the laser performs extremely well and was even able to slightly burn an unsuspecting technician's hand when held at close proximity (not recommended!). If you would like to learn more about the diode replacement process for the CUBE lasers, check out the 662nm CUBE repair back on the electronics page as the process was identical to this laser but that page goes into greater detail of the diode replacement process.

Coherent does a great job making their software and operator manuals for their products easily accessible. We were able to get this laser up and running so fast due to the accessibility of the manual and software. Links are provided below. The manual contains all of the necessary information to get one of these lasers running including pinouts and serial commands.