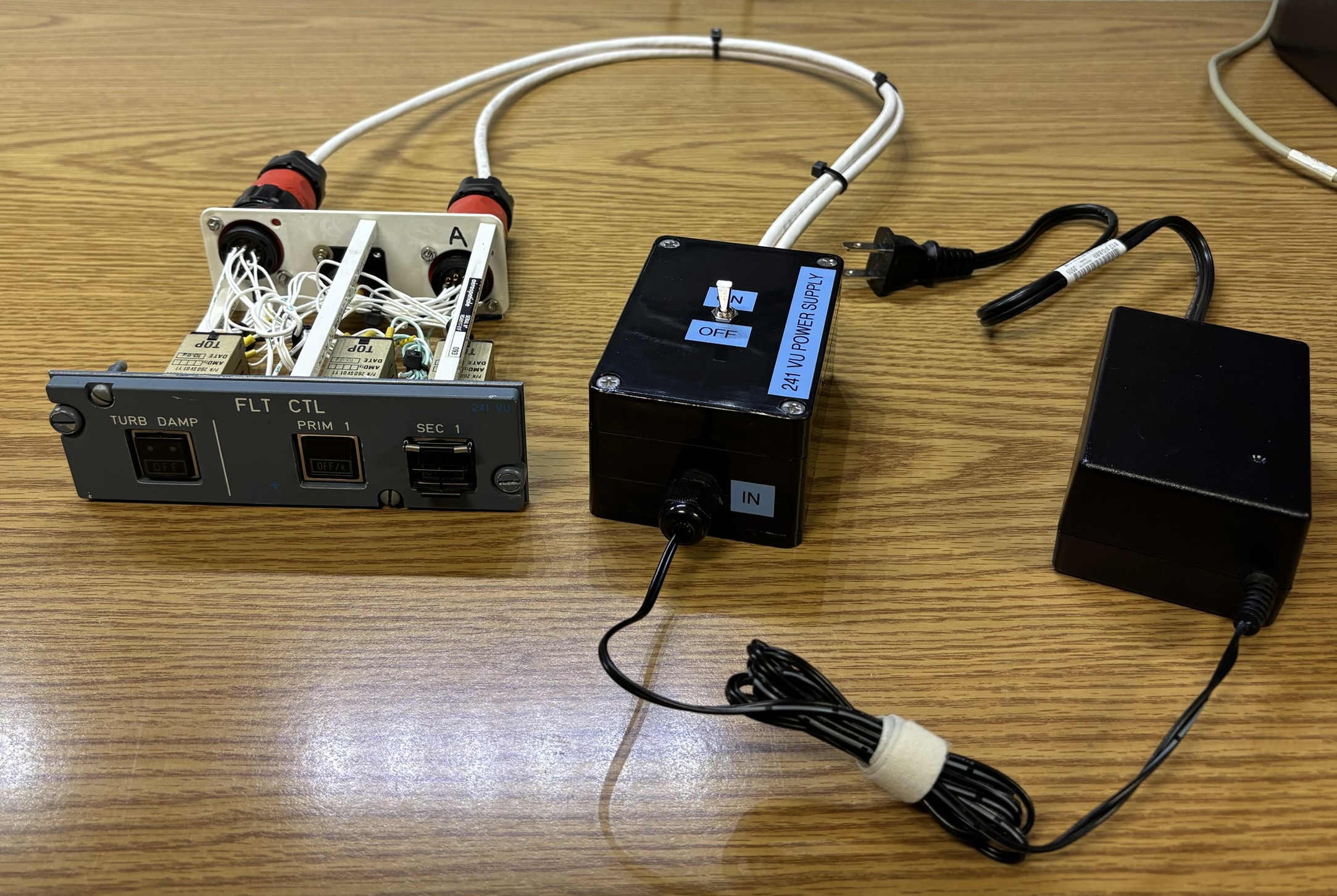

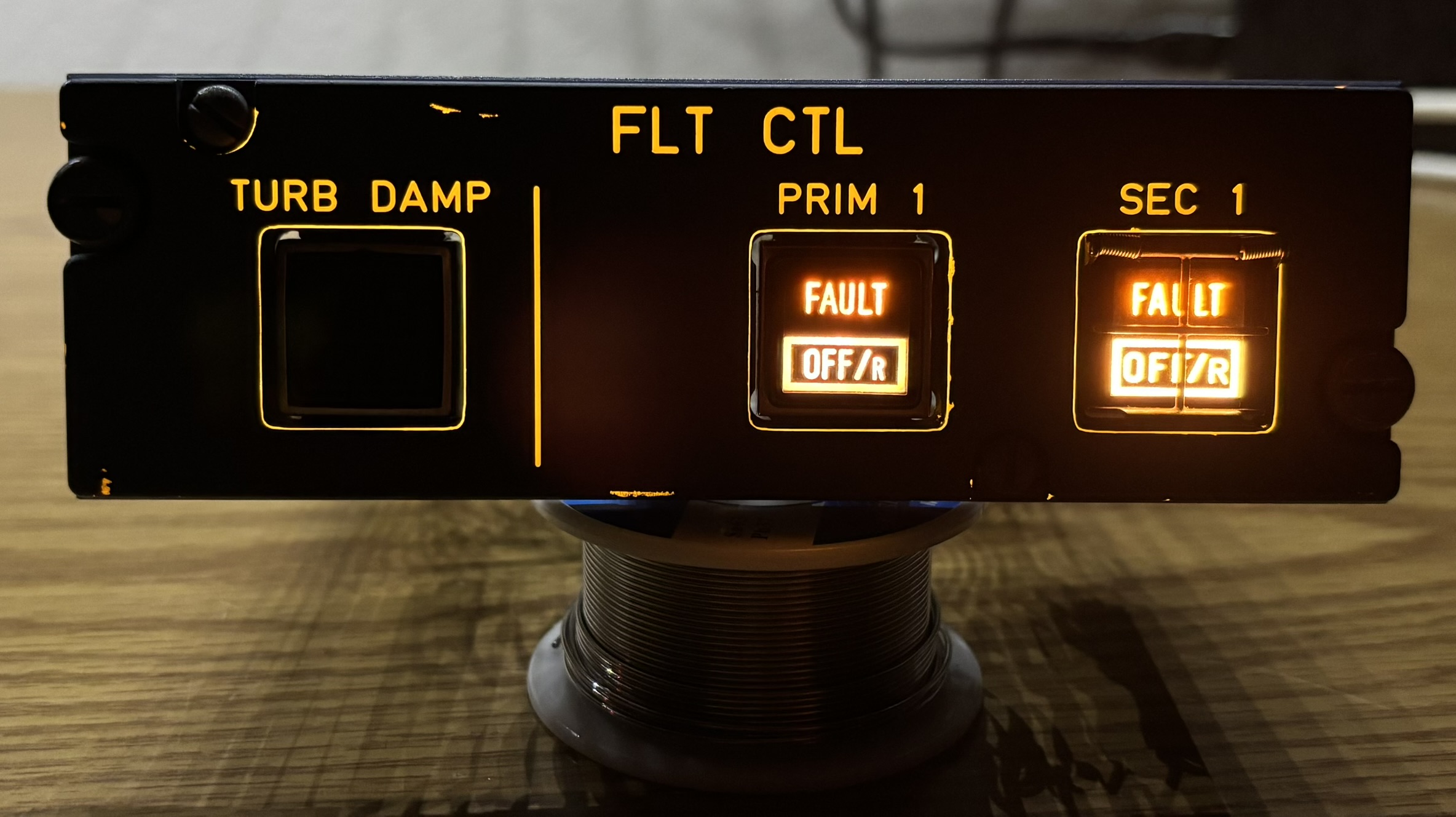

We purchased a 241VU FLT CTL panel from eBay with the intention of learning more about electrical systems in commercial aircraft. This small panel was manufactured by Aerospatiale and is dated 1995. The 241VU is one of many individual panels that would have been mounted overhead within the flight deck (cockpit) of an Airbus A330. The panel is labelled FLT CTL (flight control), includes an electronic backlight, and three pushbutton switches. The TURB DAMP switch is used to disengage the turbulence damper system if required. The PRIM 1 switch is used to turn off or reset primary flight computer 1. The SEC 1 switch is used to turn off or reset secondary flight computer 1. After deciphering the extremely complicated pin-out and locating diagrams for the switches, we chose to rewire this panel and turn it into a demo unit where the indicators change based on the states of the pushbuttons.

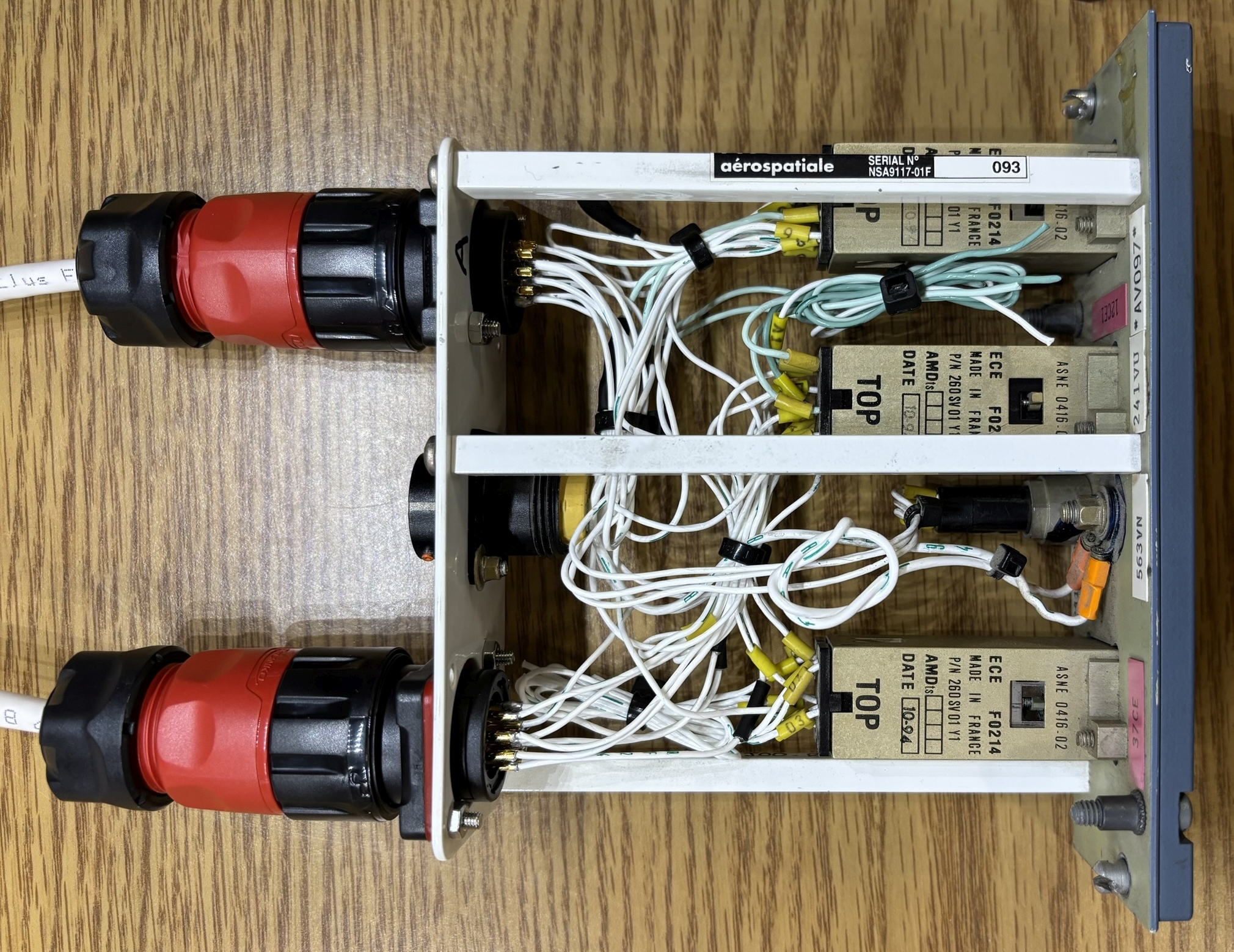

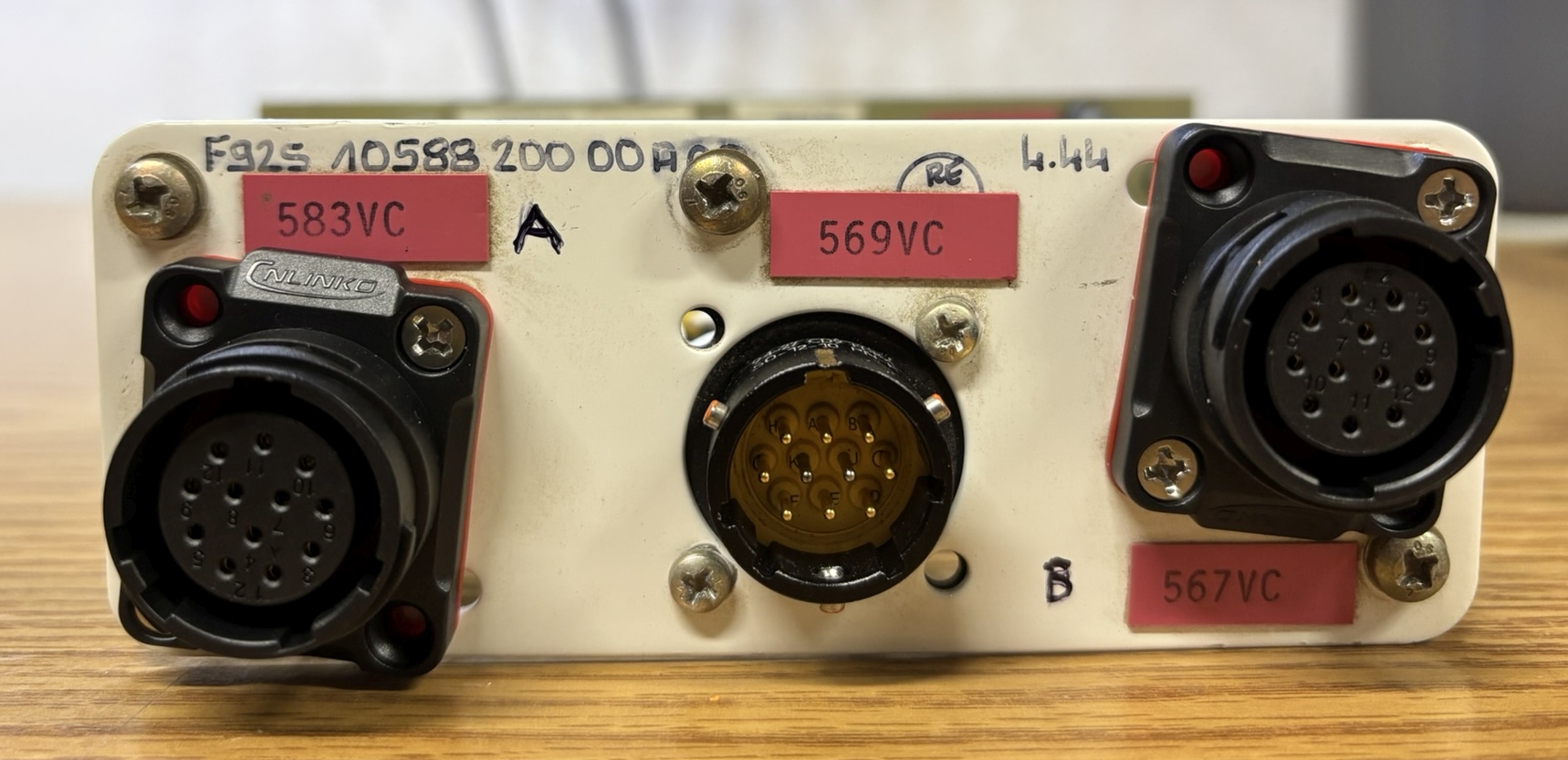

It took several hours to fully decipher the pin-outs for the switches and trace out all the wiring leading to the rear connectors. It was beyond overcomplicated, over 25 individual connections for 3 switches and some indicators. However this isn't uncommon with aviation components and avionics. Redundant connections are often necessary as the consequences of a single-point failure could be catastrophic or life threatening. Each switch had multiple connections leading to at least 2 of the 3 rear connectors. Theoretically, with this level of redundancy, an entire connector harness could be lost while retaining functionality of the switch. However we can't confirm this without first examining the equipment that the switches connect to. The actual switches are manufactured by ECE in France and follow a common standard commonly referred to as Korry 389 or Eaton 96182, who are two current manufacturers of these switches. ECE is long gone along with Aerospatiale. The switches are so complex and fascinating, that we have a separate writeup dedicated to just them! Click the link below to learn more about the switches:

We replaced two of the three original aviation twist-lock connectors. The original connectors were manufactured by EATON/Soriau, we were able to locate the mating connectors online, but they are extremely expensive and would have exceeded the budget for this project. Instead, we chose to remove and replace the connectors with some cheap alternatives from Amazon. This would not be acceptable in a commercial flight setting, but for ground demo purposes, it will suffice. The replacement connectors are manufactured by CNLINKO. We cut and soldered the necessary wires to the connectors and created some custom interface cables that feed into the power supply module.

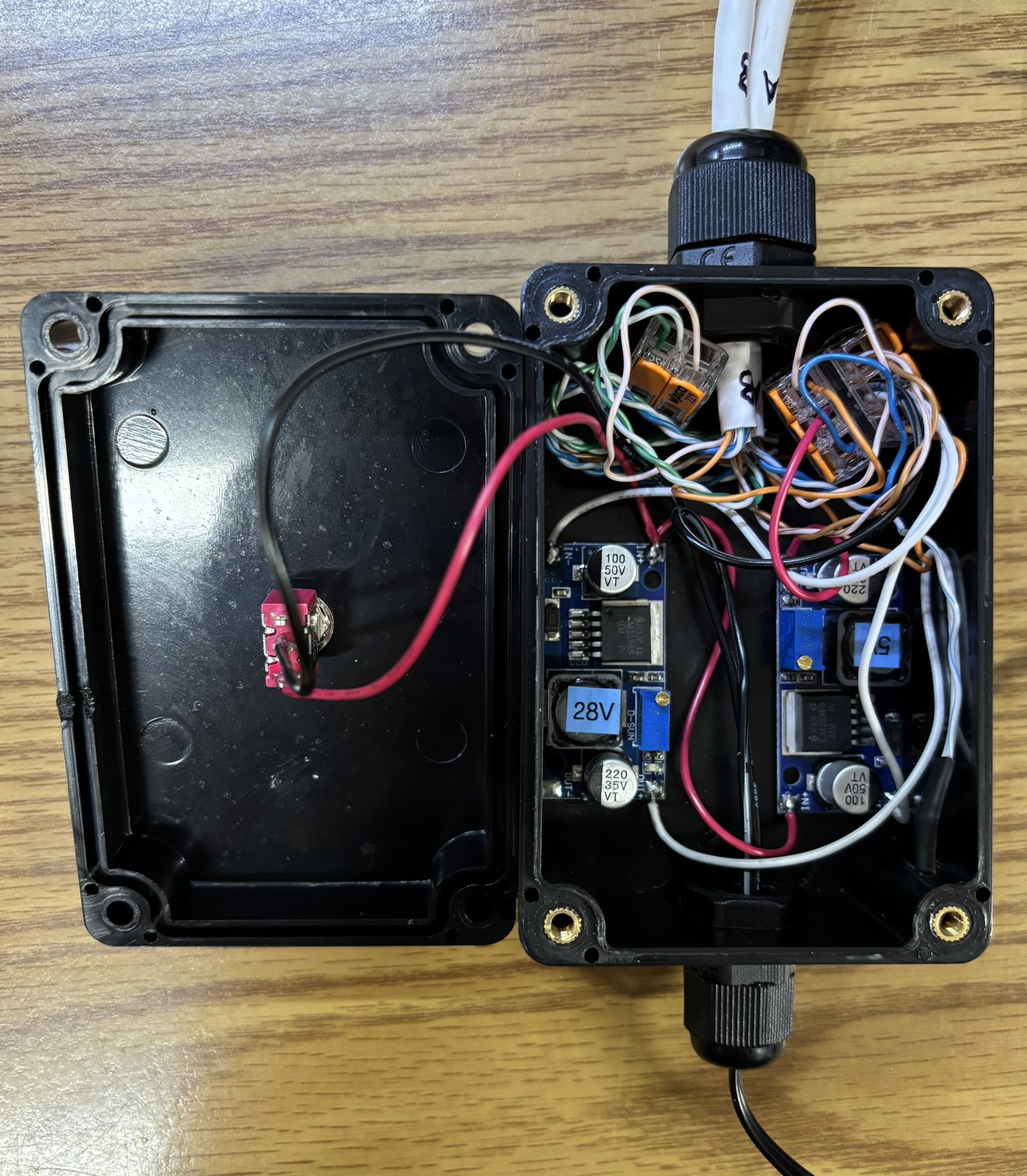

An external power supply module was custom-built to provide the various voltages needed to light up the panel. The backlight requires 28V DC and a 5V control signal. The button indicators require 5V DC. The switch on the power supply module controls power to entire panel including the backlight.

Below are some images showcasing the demo panel in action. The backlight is always on when the power supply is enabled. The TURB DAMP switch will display an OFF indicator when in the out position and controls the fault indicators on the other two switches. The PRIM 1 and SEC 1 switches will show a fault indicator and will also show an OFF/R indicator in the out position. We removed the switch guard from the PRIM 1 switch to make it easier to access for demo purposes.

Removing the two plastic slotted screws allows the backlight and label plate to be removed from the rest of the assembly. This reveals the switch enclosures and screws holding the panel together. By the way, the screws used to hold this assembly together are Torq-Set, not Phillips or Pozidriv! Attempting to use Phillips or similar drivers will result in severe damage to the Torq-Set screw heads. Buy a Torq-Set bit set if you plan to work with Torq-Set screws. It's actually a pretty clever design that allows for more torque to be applied in the loosening direction than the tightening direction, which cuts down on overtightened screws that can't be removed.

The backlight panel connects to the main assembly via an interesting connector with two concentric rings and a center pin. This allows the connector to be rotated 360 degrees if needed. The backlight panel also has the pin-out and voltages conveniently printed on a sticker above the connector!

Below are some resources that helped us learn about how these overhead panels are designed and how they work.